|

| เครื่องวัดความแข็งยางและพลาสติก Manual Durometer (ASKER) Manual Durometer Asker เครื่องวัดความแข็งยางและพลาสติก แบบเข็ม แบรนด์ ASKER

มาตรฐานสากล JIS K 6253, JIS K 7215, ASTM D 2240, ISO 7619, ISO 868, DIN 53505 MADE IN JAPAN

ASKER DUROMETER HARDNESS TESTER HIGH PERFORMANCE X SERIES Durometer Hardness Shore A Normal Rubber Durometer Hardness Shore D Hard Rubber and Plastics Durometer Hardness Shore C Soft Rubber and Sponge Durometer Hardness Shore F Urethane foam, Sponge and polystyrene foam

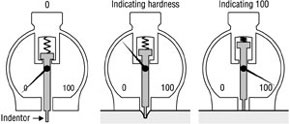

As the hardness tester is pressed against the sample, the material resistance force and indentor spring load balance. The depth of the indentor is measured, which provides a measure of the material's hardness. Values are based upon a 100 point scale (accuracy ±.75 point). However, as time elapses the indicator will "creep" back so that a reading taken a few seconds after the tester makes contact with the sample will be less than the peak reading. The optional peak indicator helps to more closely monitor the difference between peak and "creep" in hardness tests.

Common Hardness scales :

Durometer Asker Specifications Indication Range : 262 degree dial scale Minimum indication : 1 point ( Accuracy : + - 1 Point ) Pressure foot Dimensions : 44 x 18 mm Rectangular Outer Dimensions : Approx. Width 57 x Depth 30 x Height 76 mm Mounting Thread : M6 P1 Weight : 200 Grams

ASKER TYPE PICTURE

Asker Serires Durometer

|

เครื่องวัดความแข็งยางและพลาสติก Manual Durometer (CHECKLINE) HP-TEXTILE เครื่องวัดความแข็งยางและพลาสติก Manual Durometer (CHECKLINE) HP-TEXTILE  เครื่องวัดความแข็งยางและพลาสติก Manual Durometer (CHECKLINE) RX-3000 เครื่องวัดความแข็งยางและพลาสติก Manual Durometer (CHECKLINE) RX-3000  เครื่องวัดความแข็งยางและพลาสติกขายาวร่องลึก Manual Durometer (CHECKLINE) RX-1600 เครื่องวัดความแข็งยางและพลาสติกขายาวร่องลึก Manual Durometer (CHECKLINE) RX-1600  เครื่องวัดความแข็งยางและพลาสติก Manual Durometer (DESIK) เครื่องวัดความแข็งยางและพลาสติก Manual Durometer (DESIK)  เครื่องวัดความแข็งยางและพลาสติกขายาวร่องลึก Manual Durometer (CHECKLINE) เครื่องวัดความแข็งยางและพลาสติกขายาวร่องลึก Manual Durometer (CHECKLINE)  เครื่องวัดความแข็งยางและพลาสติก Manual Durometer (CHECKLINE) เครื่องวัดความแข็งยางและพลาสติก Manual Durometer (CHECKLINE)  เครื่องวัดความแข็งยางและพลาสติก Manual Durometer (TECLOCK) เครื่องวัดความแข็งยางและพลาสติก Manual Durometer (TECLOCK)  เครื่องวัดความแข็งยางและพลาสติก Manual Durometer (ASKER) EX เครื่องวัดความแข็งยางและพลาสติก Manual Durometer (ASKER) EX  เครื่องวัดความแข็งยางและพลาสติก Manual Durometer (CHECKLINE) AD-100 เครื่องวัดความแข็งยางและพลาสติก Manual Durometer (CHECKLINE) AD-100  เครื่องวัดความแข็งยางและพลาสติก Manual Durometer (IMADA) E2 เครื่องวัดความแข็งยางและพลาสติก Manual Durometer (IMADA) E2  เครื่องวัดความแข็งยางและพลาสติก Manual Durometer (CHECKLINE) HP-SERIES เครื่องวัดความแข็งยางและพลาสติก Manual Durometer (CHECKLINE) HP-SERIES  เครื่องวัดความแข็งยางและพลาสติก Manual Durometer (DESIK) Shore F เครื่องวัดความแข็งยางและพลาสติก Manual Durometer (DESIK) Shore F  เครื่องวัดความแข็งยางและพลาสติก Manual Durometer (DESIK) Shore O เครื่องวัดความแข็งยางและพลาสติก Manual Durometer (DESIK) Shore O  เครื่องวัดความแข็งยางและพลาสติก Manual Durometer (DESIK) Shore C เครื่องวัดความแข็งยางและพลาสติก Manual Durometer (DESIK) Shore C  เครื่องวัดความแข็งยางและพลาสติก Manual Durometer (DESIK) Shore A เครื่องวัดความแข็งยางและพลาสติก Manual Durometer (DESIK) Shore A  เครื่องวัดความแข็งยางและพลาสติก Manual Durometer (DESIK) Shore D เครื่องวัดความแข็งยางและพลาสติก Manual Durometer (DESIK) Shore D  เครื่องวัดความแข็งยางและพลาสติก Digital Durometer (CHECKLINE) RX-DD-ASK-C-SS เครื่องวัดความแข็งยางและพลาสติก Digital Durometer (CHECKLINE) RX-DD-ASK-C-SS  เครื่องวัดความแข็งยางและพลาสติก Digital Durometer (CHECKLINE) RX-4000 เครื่องวัดความแข็งยางและพลาสติก Digital Durometer (CHECKLINE) RX-4000  เครื่องวัดความแข็งยางและพลาสติก Digital Durometer (CHECKLINE) DD-100 เครื่องวัดความแข็งยางและพลาสติก Digital Durometer (CHECKLINE) DD-100  เครื่องวัดความแข็งยางและพลาสติก Digital Durometer (CHECKLINE) เครื่องวัดความแข็งยางและพลาสติก Digital Durometer (CHECKLINE)  เครื่องวัดความแข็งยางและพลาสติก Digital Durometer (TECLOCK) เครื่องวัดความแข็งยางและพลาสติก Digital Durometer (TECLOCK)  เครื่องวัดความแข็งยางและพลาสติก Digital Durometer (DESIK) Shore D เครื่องวัดความแข็งยางและพลาสติก Digital Durometer (DESIK) Shore D  เครื่องวัดความแข็งยางและพลาสติก Digital Durometer (DESIK) Shore C เครื่องวัดความแข็งยางและพลาสติก Digital Durometer (DESIK) Shore C  เครื่องวัดความแข็งยางและพลาสติก Digital Durometer (DESIK) Shore A เครื่องวัดความแข็งยางและพลาสติก Digital Durometer (DESIK) Shore A  เครื่องวัดความแข็งยางและพลาสติกขายาวร่องลึก Digital Durometer (DESIK) เครื่องวัดความแข็งยางและพลาสติกขายาวร่องลึก Digital Durometer (DESIK)  Durometer Block Kits แผ่นทดสอบความแข็งยาง Durometer Block Kits แผ่นทดสอบความแข็งยาง  แท่นยึดเครื่องความแข็งยางและพลาสติก Stand Durometer (DESIK) Shore A และ C แท่นยึดเครื่องความแข็งยางและพลาสติก Stand Durometer (DESIK) Shore A และ C  แท่นยึดเครื่องความแข็งยางและพลาสติก Stand Durometer (DESIK) Shore D แท่นยึดเครื่องความแข็งยางและพลาสติก Stand Durometer (DESIK) Shore D  เครื่องวัดความแข็งยางและพลาสติก Digital Durometer iShore-100 (Mikrosize) เครื่องวัดความแข็งยางและพลาสติก Digital Durometer iShore-100 (Mikrosize)  เครื่องวัดความแข็งยางและพลาสติก Fully Automatic Digital Durometer Digi-Test-II (CHECKLINE) เครื่องวัดความแข็งยางและพลาสติก Fully Automatic Digital Durometer Digi-Test-II (CHECKLINE)  เครื่องวัดความแข็งยางและพลาสติก Digital Durometer RX-DD-5 (CHECKLINE) เครื่องวัดความแข็งยางและพลาสติก Digital Durometer RX-DD-5 (CHECKLINE)  เครื่องวัดความแข็งยางและพลาสติก Digital Durometer RX-DD (CHECKLINE) เครื่องวัดความแข็งยางและพลาสติก Digital Durometer RX-DD (CHECKLINE)  เครื่องวัดความแข็งยางและพลาสติก Digital Durometer HPE-PJ (CHECKLINE) เครื่องวัดความแข็งยางและพลาสติก Digital Durometer HPE-PJ (CHECKLINE)  เครื่องวัดความแข็งยางและพลาสติก Digital Durometer HPE-III-A (CHECKLINE) เครื่องวัดความแข็งยางและพลาสติก Digital Durometer HPE-III-A (CHECKLINE)  เครื่องวัดความแข็งยางและพลาสติก Basic Digital Durometer HP Digital(CHECKLINE) เครื่องวัดความแข็งยางและพลาสติก Basic Digital Durometer HP Digital(CHECKLINE)  เครื่องวัดความแข็งยางและพลาสติก Digital Durometer with Output TKD TKX (CHECKLINE) เครื่องวัดความแข็งยางและพลาสติก Digital Durometer with Output TKD TKX (CHECKLINE)  เครื่องสอบเทียบความแข็งยางและพลาสติก Durometer Calibrator RDC-1 (CHECKLINE) เครื่องสอบเทียบความแข็งยางและพลาสติก Durometer Calibrator RDC-1 (CHECKLINE)  เครื่องวัดความแข็งยางและพลาสติก Manual Durometer RX-2100 (CHECKLINE) เครื่องวัดความแข็งยางและพลาสติก Manual Durometer RX-2100 (CHECKLINE)  เครื่องวัดความแข็งยางและพลาสติก Manual Durometer HPSAO (CHECKLINE) เครื่องวัดความแข็งยางและพลาสติก Manual Durometer HPSAO (CHECKLINE)  เครื่องวัดความแข็งยางและพลาสติก Manual Durometer E2-Series (CHECKLINE) เครื่องวัดความแข็งยางและพลาสติก Manual Durometer E2-Series (CHECKLINE)  เครื่องวัดความแข็งยางและพลาสติก Manual Durometer RX-1600-A120 (CHECKLINE) เครื่องวัดความแข็งยางและพลาสติก Manual Durometer RX-1600-A120 (CHECKLINE)  เครื่องวัดความแข็งยางและพลาสติก Manual Durometer RX-1000 (CHECKLINE) เครื่องวัดความแข็งยางและพลาสติก Manual Durometer RX-1000 (CHECKLINE)  เครื่องวัดความแข็งยางและพลาสติก Manual Durometer RX-MS (CHECKLINE) เครื่องวัดความแข็งยางและพลาสติก Manual Durometer RX-MS (CHECKLINE)  เครื่องวัดความแข็งยางและพลาสติก Manual Durometer HPSA-R (CHECKLINE) เครื่องวัดความแข็งยางและพลาสติก Manual Durometer HPSA-R (CHECKLINE)  เครื่องวัดความแข็งยางและพลาสติก Manual Durometer RX-2000 Max-Hand Durometer (CHECKLINE) เครื่องวัดความแข็งยางและพลาสติก Manual Durometer RX-2000 Max-Hand Durometer (CHECKLINE)  แผ่นทดสอบความแข็ง Shore A and Shore D Durometer Kit RX-MS-A-D-KIT (CHECKLINE) แผ่นทดสอบความแข็ง Shore A and Shore D Durometer Kit RX-MS-A-D-KIT (CHECKLINE)  HP-Bareiss Bareiss HP Analog Durometer HP-Bareiss Bareiss HP Analog Durometer  เครื่องวัดความแข็งยางและพลาสติก Manual Durometer RX-SP Series (CHECKLINE) เครื่องวัดความแข็งยางและพลาสติก Manual Durometer RX-SP Series (CHECKLINE)  เครื่องวัดความแข็งยาง Digital Durometer PT-SHD (Defelsko) เครื่องวัดความแข็งยาง Digital Durometer PT-SHD (Defelsko)  เครื่องวัดความแข็งยางและพลาสติก Digital Durometer (TIME) Shore A 5430 เครื่องวัดความแข็งยางและพลาสติก Digital Durometer (TIME) Shore A 5430  เครื่องวัดความแข็งยางและพลาสติก Digital Durometer (TIME) Shore D 5431 เครื่องวัดความแข็งยางและพลาสติก Digital Durometer (TIME) Shore D 5431  เครื่องวัดความแข็งยางและพลาสติก Manual Durometer Shore OO เครื่องวัดความแข็งยางและพลาสติก Manual Durometer Shore OO  เครื่องวัดความแข็งยางและพลาสติก Micro IRHD System IM-5 (KOREA) เครื่องวัดความแข็งยางและพลาสติก Micro IRHD System IM-5 (KOREA)  เครื่องวัดความแข็งยางและพลาสติก Vernier Durometer (CHECKLINE) เครื่องวัดความแข็งยางและพลาสติก Vernier Durometer (CHECKLINE)  เครื่องสอบเทียบสำหรับเครื่องวัดความแข็งยางและพลาสติก Durometer Calibration (CHECKLINE) RDC-1 เครื่องสอบเทียบสำหรับเครื่องวัดความแข็งยางและพลาสติก Durometer Calibration (CHECKLINE) RDC-1  เครื่องวัดความแข็งยางและพลาสติก Digital Durometer (DESIK) เครื่องวัดความแข็งยางและพลาสติก Digital Durometer (DESIK)  Digital Durometer เครื่องวัดความแข็งยาง Micro IRHD System ITK-D01 Digital Durometer เครื่องวัดความแข็งยาง Micro IRHD System ITK-D01  Durometer Hardness Meter เครื่องทดสอบความแข็งยางและพลาสติก ชนิดตั้งโต๊ะ GX-01 Serires Durometer Hardness Meter เครื่องทดสอบความแข็งยางและพลาสติก ชนิดตั้งโต๊ะ GX-01 Serires  Durometer Hardness Meter เครื่องทดสอบความแข็งยางและพลาสติก ชนิดตั้งโต๊ะ IRHD GS-680 Durometer Hardness Meter เครื่องทดสอบความแข็งยางและพลาสติก ชนิดตั้งโต๊ะ IRHD GS-680 |