|

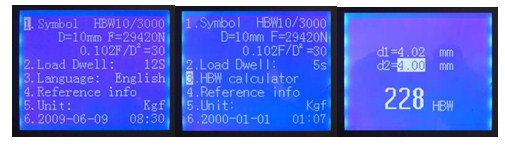

| เครื่องทดสอบความแข็งโลหะ Hardness Tester Brinell 900-356 Series (Phase ll) เครื่องทดสอบความแข็งโลหะ Hardness Tester Brinell 900-356 Series (Phase ll) เครื่องทดสอบความแข็ง Brinell แบรนด์ Phase ll เครื่องทดสอบความแข็งที่แม่นยำ หน้าจอแสดงผลแบบดิจิตอล ออกแบบมาเพื่อการอ่านที่รวดเร็วเหมาะสำหรับการวิเคราะห์ความแข็งของชิ้นงานโลหะ โลหะ ทองแดง สังกะสี ทองเหลือง อลูมิเนียม ได้ สามารถติดต่อสอบถามได้ที่ 02-9744354-6 สายด่วน 088-7777277

Specifications:

Technical data:

|

Brinell Hardness Tester เครื่องทดสอบความแข็งแบบตั้งโต๊ะชนิด Brinell

เครื่องทดสอบความแข็งโลหะ Brinell Hardness Tester รุ่น Marble เครื่องทดสอบความแข็งโลหะ Brinell Hardness Tester รุ่น Marble  เครื่องทดสอบความแข็งโลหะ Hardness Tester Brinell LHB-3000C เครื่องทดสอบความแข็งโลหะ Hardness Tester Brinell LHB-3000C  Standard Weight Digital Brinell Hardness Tester HBS-3000B Standard Weight Digital Brinell Hardness Tester HBS-3000B  Electronic Loading Digital Brinell Hardness Tester HBS-3000 Electronic Loading Digital Brinell Hardness Tester HBS-3000  Computerized Image Brinell Hardness Tester HBST-3000Z Computerized Image Brinell Hardness Tester HBST-3000Z  Small load automatic turret digital display Brinell hardness tester HBS-62.5Z Small load automatic turret digital display Brinell hardness tester HBS-62.5Z  PHB-750 Magnetic Hydraulic Brinell Hardness Tester PHB-750 Magnetic Hydraulic Brinell Hardness Tester  PHB-3000a Chain Hydraulic Brinell Hardness Tester PHB-3000a Chain Hydraulic Brinell Hardness Tester  PHB-3000 Hydraulic Brinell Hardness Tester PHB-3000 Hydraulic Brinell Hardness Tester  PHB-150 Pin Static Brinell Hardness Tester PHB-150 Pin Static Brinell Hardness Tester  PHB-200 Digital Magnetic Brinell Hardness Tester PHB-200 Digital Magnetic Brinell Hardness Tester  PHB-300 Automatic Magnetic Brinell Hardness Tester PHB-300 Automatic Magnetic Brinell Hardness Tester  MS-1A Brinell Indentation Measurement System MS-1A Brinell Indentation Measurement System  MS-1B Brinell Indentation Measurement System MS-1B Brinell Indentation Measurement System  MS-2A Brinell Indentation Measurement System MS-2A Brinell Indentation Measurement System  กล้องจุลทรรศน์อ่านข้อมูลเครื่องทดสอบความแข็ง Brinell แบบพกพา JC-Series กล้องจุลทรรศน์อ่านข้อมูลเครื่องทดสอบความแข็ง Brinell แบบพกพา JC-Series  เครื่องทดสอบความแข็งโลหะ Hardness Tester Brinell HT-BD3000T เครื่องทดสอบความแข็งโลหะ Hardness Tester Brinell HT-BD3000T  เครื่องทดสอบความแข็งแบบตั้งโต๊ะชนิด Rockwell PrimeR-560Z (SUNPOC) เครื่องทดสอบความแข็งแบบตั้งโต๊ะชนิด Rockwell PrimeR-560Z (SUNPOC)  เครื่องทดสอบความแข็งโลหะ Hardness Tester Brinell SHB-3011X (SUNPOC) เครื่องทดสอบความแข็งโลหะ Hardness Tester Brinell SHB-3011X (SUNPOC)  เครื่องทดสอบความแข็งโลหะ Hardness Tester Brinell SHB-3011S (SUNPOC) เครื่องทดสอบความแข็งโลหะ Hardness Tester Brinell SHB-3011S (SUNPOC)  เครื่องทดสอบความแข็งโลหะ Hardness Tester Brinell SHB-3011D (SUNPOC) เครื่องทดสอบความแข็งโลหะ Hardness Tester Brinell SHB-3011D (SUNPOC)  เครื่องทดสอบความแข็งโลหะ Hardness Tester Brinell TB-B-CM (NOVOTEST) เครื่องทดสอบความแข็งโลหะ Hardness Tester Brinell TB-B-CM (NOVOTEST)  เครื่องทดสอบความแข็งโลหะ Hardness Tester Brinell TB-B-C (NOVOTEST) เครื่องทดสอบความแข็งโลหะ Hardness Tester Brinell TB-B-C (NOVOTEST)  เครื่องทดสอบความแข็งโลหะ Hardness Tester Brinell 900-357 Series (Phase ll) เครื่องทดสอบความแข็งโลหะ Hardness Tester Brinell 900-357 Series (Phase ll)  เครื่องทดสอบความแข็งโลหะ Hardness Tester Brinell 900-359 Series (Phase ll) เครื่องทดสอบความแข็งโลหะ Hardness Tester Brinell 900-359 Series (Phase ll)  เครื่องทดสอบความแข็งโลหะ Hardness Tester Brinell 900-355 Series (Phase ll) เครื่องทดสอบความแข็งโลหะ Hardness Tester Brinell 900-355 Series (Phase ll)  กล้องต่อสำหรับHardness Tester Brinell XC Series กล้องต่อสำหรับHardness Tester Brinell XC Series  เครื่องทดสอบความแข็งโลหะ Hardness Tester Brinell BO3 เครื่องทดสอบความแข็งโลหะ Hardness Tester Brinell BO3  เครื่องทดสอบความแข็งโลหะ Hardness Tester Brinell HBE-3000S เครื่องทดสอบความแข็งโลหะ Hardness Tester Brinell HBE-3000S  เครื่องทดสอบความแข็งโลหะ Hardness Tester Brinell ITK-ZHB3000A Fully Automatic Three เครื่องทดสอบความแข็งโลหะ Hardness Tester Brinell ITK-ZHB3000A Fully Automatic Three  เครื่องทดสอบความแข็งโลหะ Hardness Tester Brinell ITK-HBST3000 Electric Load เครื่องทดสอบความแข็งโลหะ Hardness Tester Brinell ITK-HBST3000 Electric Load  เครื่องทดสอบความแข็งโลหะ Hardness Tester Brinell ITK-HBS3000 เครื่องทดสอบความแข็งโลหะ Hardness Tester Brinell ITK-HBS3000  เครื่องทดสอบความแข็งโลหะ Hardness Tester Brinell ITK-BMS-3000-OBLC เครื่องทดสอบความแข็งโลหะ Hardness Tester Brinell ITK-BMS-3000-OBLC  เครื่องทดสอบความแข็งโลหะ Hardness Tester Brinell ITK-HB3000B เครื่องทดสอบความแข็งโลหะ Hardness Tester Brinell ITK-HB3000B  เครื่องทดสอบความแข็งโลหะ Hardness Tester Brinell ITK-BMS3000-OBPC เครื่องทดสอบความแข็งโลหะ Hardness Tester Brinell ITK-BMS3000-OBPC  เครื่องทดสอบความแข็งโลหะ Hardness Tester Brinell HBE-3000M เครื่องทดสอบความแข็งโลหะ Hardness Tester Brinell HBE-3000M  เครื่องทดสอบความแข็งโลหะ Hardness Tester Brinell MHBD-3000P เครื่องทดสอบความแข็งโลหะ Hardness Tester Brinell MHBD-3000P  เครื่องทดสอบความแข็งโลหะ Hardness Tester Brinell MHBD-3000T เครื่องทดสอบความแข็งโลหะ Hardness Tester Brinell MHBD-3000T  เครื่องทดสอบความแข็งโลหะ Hardness Tester Brinell SHB-3000XZT เครื่องทดสอบความแข็งโลหะ Hardness Tester Brinell SHB-3000XZT  เครื่องทดสอบความแข็งโลหะ Hardness Tester Brinell SHB-3000XZM เครื่องทดสอบความแข็งโลหะ Hardness Tester Brinell SHB-3000XZM  เครื่องทดสอบความแข็งโลหะ Hardness Tester Brinell SHB-3000XZ เครื่องทดสอบความแข็งโลหะ Hardness Tester Brinell SHB-3000XZ  เครื่ื่องทดสอบความแข็งโลหะ Hardness Tester Brinell ITK-1 เครื่ื่องทดสอบความแข็งโลหะ Hardness Tester Brinell ITK-1  เครื่องทดสอบความแข็งโลหะ Hardness Tester Brinell Xbrin-S103 เครื่องทดสอบความแข็งโลหะ Hardness Tester Brinell Xbrin-S103  เครื่องทดสอบความแข็งโลหะ Hardness Tester Brinell SHB-3000D/X/M เครื่องทดสอบความแข็งโลหะ Hardness Tester Brinell SHB-3000D/X/M  เครื่องทดสอบความแข็งโลหะ Hardness Tester Brinell KHB-3000A เครื่องทดสอบความแข็งโลหะ Hardness Tester Brinell KHB-3000A |