|

| เครื่องวัดความหนาสี Coating Thickness Gauge Minitest-745(Minitest) เครื่องวัดความหนาสี Coating Thickness Gauge Minitest-745(Minitest)

MiniTest 745

Designed for utmost flexibility for quality control and inspections, the sensor of the MiniTest 745 model can be easily converted from an integral probe to a cabled probe setup. So even difficult to access areas can be reached without problems.

Features

Accessories

Specifications

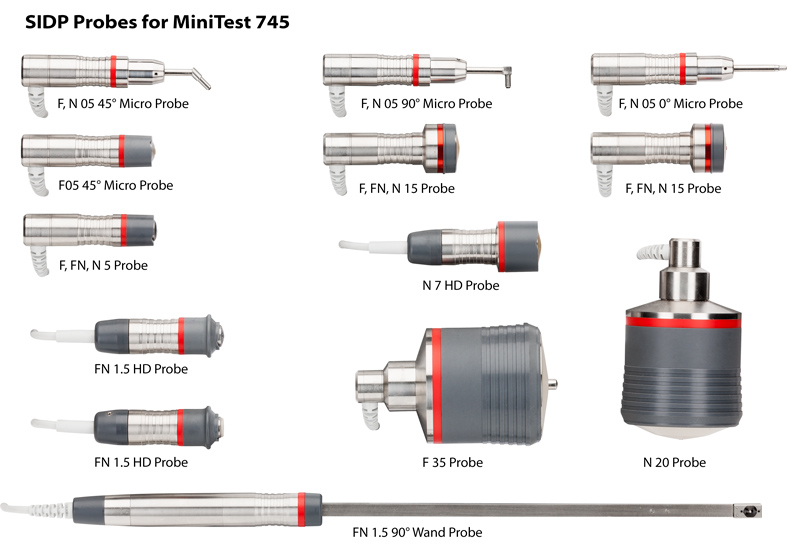

Probes

|

เครื่องวัดความหนาสี Coating Thickness Gauge Surfix Special purpose gauges(PHYNIX) เครื่องวัดความหนาสี Coating Thickness Gauge Surfix Special purpose gauges(PHYNIX)  เครื่องวัดความหนาสี Coating Thickness Gauge Surfix PaintCheck (PHYNIX) เครื่องวัดความหนาสี Coating Thickness Gauge Surfix PaintCheck (PHYNIX)  เครื่องวัดความหนาสี Coating Thickness Gauge Surfix EASY-X (PHYNIX) เครื่องวัดความหนาสี Coating Thickness Gauge Surfix EASY-X (PHYNIX)  เครื่องวัดความหนาสี Coating Thickness Gauge Surfix Pro EX-SX (PHYNIX) เครื่องวัดความหนาสี Coating Thickness Gauge Surfix Pro EX-SX (PHYNIX)  เครื่องวัดความหนาสี Coating Thickness Gauge Surfix Pro X (PHYNIX) เครื่องวัดความหนาสี Coating Thickness Gauge Surfix Pro X (PHYNIX)  เครื่องวัดความหนาสี Coating Thickness Gauge Surfix-Pro/Pro S (PHYNIX) เครื่องวัดความหนาสี Coating Thickness Gauge Surfix-Pro/Pro S (PHYNIX)  เครื่องวัดความหนาสี Coating Thickness Gauge Surfix E Family (PHYNIX) เครื่องวัดความหนาสี Coating Thickness Gauge Surfix E Family (PHYNIX)  เครื่องวัดความหนาสี บนไม้,ปูน,พลาสติก เครื่องวัดความหนาสี บนไม้,ปูน,พลาสติก  เครื่องวัดความหนาสี Coating Thickness Gauge iCoat-320 เครื่องวัดความหนาสี Coating Thickness Gauge iCoat-320  เครื่องวัดความหนาสี Coating Thickness Gauge QuintSonic-T (ElektroPhysik) เครื่องวัดความหนาสี Coating Thickness Gauge QuintSonic-T (ElektroPhysik)  เครื่องทดสอบความหนาสี Coating Thickness Gauge Positest-PC (Defelsko) เครื่องทดสอบความหนาสี Coating Thickness Gauge Positest-PC (Defelsko)  เครื่องวัดความหนาสี Electromagnetic/Eddy Current Coating Thickness Meters (Sanko) เครื่องวัดความหนาสี Electromagnetic/Eddy Current Coating Thickness Meters (Sanko)  เครื่องวัดความหนาสี Coating Thickness Gauge SWT-7000IV-Series (Sanko) เครื่องวัดความหนาสี Coating Thickness Gauge SWT-7000IV-Series (Sanko)  เครื่องวัดความหนาสี Coating Thickness Gauge NT-2S (Nohawk) เครื่องวัดความหนาสี Coating Thickness Gauge NT-2S (Nohawk)  เครื่องวัดความหนาสี Coating Thickness Gauge TP-2020 (NOVOTEST) เครื่องวัดความหนาสี Coating Thickness Gauge TP-2020 (NOVOTEST)  เครื่องวัดความหนาสี Coating Thickness Tester (wireless model) L-200W series [Discontinued] (KETT JAPAN) เครื่องวัดความหนาสี Coating Thickness Tester (wireless model) L-200W series [Discontinued] (KETT JAPAN)  เครื่องวัดความหนาสี Dual-Type Coating Thickness Tester LZ-990 ESCAL(KETT JAPAN) เครื่องวัดความหนาสี Dual-Type Coating Thickness Tester LZ-990 ESCAL(KETT JAPAN)  เครื่องวัดความหนาสีDual-Type Coating Thickness Tester LZ-373 (KETT JAPAN) เครื่องวัดความหนาสีDual-Type Coating Thickness Tester LZ-373 (KETT JAPAN)  เครื่องวัดความหนาสีDual-Type Coating Thickness Tester LZ-200J(KETT JAPAN) เครื่องวัดความหนาสีDual-Type Coating Thickness Tester LZ-200J(KETT JAPAN)  เครื่องวัดความหนาสีEddy-current Coating Thickness Tester LH-373(KETT JAPAN) เครื่องวัดความหนาสีEddy-current Coating Thickness Tester LH-373(KETT JAPAN)  เครื่องวัดความหนาสีEddy-current Coating Thickness Tester LH-200J(KETT JAPAN) เครื่องวัดความหนาสีEddy-current Coating Thickness Tester LH-200J(KETT JAPAN)  เครื่องวัดความหนาสีElectromagnetic Coating Thickness Tester LE-373 (KETT JAPAN) เครื่องวัดความหนาสีElectromagnetic Coating Thickness Tester LE-373 (KETT JAPAN)  เครื่องวัดความหนาสีElectromagnetic Coating Thickness Tester LE-200J (KETT JAPAN) เครื่องวัดความหนาสีElectromagnetic Coating Thickness Tester LE-200J (KETT JAPAN)  เครื่องวัดความหนาสี Coating Thickness Gauge L-500 (KETT JAPAN) เครื่องวัดความหนาสี Coating Thickness Gauge L-500 (KETT JAPAN)  เครื่องวัดความหนาสี Coating Thickness Gauge Surfix Pro S-CT for car tyre (PHYNIX) เครื่องวัดความหนาสี Coating Thickness Gauge Surfix Pro S-CT for car tyre (PHYNIX)  เครื่องวัดความหนาสี Dual Coating Thickness Meters SWT-7000Ⅲ เครื่องวัดความหนาสี Dual Coating Thickness Meters SWT-7000Ⅲ  เครื่องวัดความหนาสี Coating Thickness Gauge ED-400 (TX) เครื่องวัดความหนาสี Coating Thickness Gauge ED-400 (TX)  เครื่องวัดความหนาสี Coating Thickness Gauge TM-007 เครื่องวัดความหนาสี Coating Thickness Gauge TM-007  เครื่องวัดความหนาสี Coating Thickness Gauge NT-1S เครื่องวัดความหนาสี Coating Thickness Gauge NT-1S  เครื่องวัดความหนาสี Coating Thickness Gauge PTE (Paint Test Equipment) เครื่องวัดความหนาสี Coating Thickness Gauge PTE (Paint Test Equipment)  เครื่องวัดความหนาสี Coating Thickness Gauge Minitest-SmarTest(Minitest) เครื่องวัดความหนาสี Coating Thickness Gauge Minitest-SmarTest(Minitest)  เครื่องวัดความหนาสี Coating Thickness Gauge Minitest-735(Minitest) เครื่องวัดความหนาสี Coating Thickness Gauge Minitest-735(Minitest)  เครื่องวัดความหนาสี Coating Thickness Gauge Minitest-725(Minitest) เครื่องวัดความหนาสี Coating Thickness Gauge Minitest-725(Minitest)  เครื่องวัดความหนาสี Coating Thickness Gauge Minitest-2500-4500(Minitest) เครื่องวัดความหนาสี Coating Thickness Gauge Minitest-2500-4500(Minitest)  เครื่องวัดความหนาสี Coating PIG เครื่องวัดความหนาสี Coating PIG  เครื่องวัดความหนาสี Coating Thickness Gauge TIME-2500 เครื่องวัดความหนาสี Coating Thickness Gauge TIME-2500  เครื่องวัดความหนาสี Coating Thickness Gauge TIME-2501 เครื่องวัดความหนาสี Coating Thickness Gauge TIME-2501  เครื่องวัดความหนาสี Coating Thickness Gauge TIME-2511 เครื่องวัดความหนาสี Coating Thickness Gauge TIME-2511  เครื่องวัดความหนาสี Coating Thickness Gauge TIME-2510 เครื่องวัดความหนาสี Coating Thickness Gauge TIME-2510  เครื่องวัดความหนาสี Coating Thickness Gauge TIME-2600 เครื่องวัดความหนาสี Coating Thickness Gauge TIME-2600  เครื่องวัดความหนาสี Coating Thickness Gauge TIME-2605 เครื่องวัดความหนาสี Coating Thickness Gauge TIME-2605  เครื่องวัดความหนาสี Coating Thickness Gauge TIME-2603 เครื่องวัดความหนาสี Coating Thickness Gauge TIME-2603  เครื่องวัดความหนาสี Coating Thickness Gauge PTG-3725(Phase ll) เครื่องวัดความหนาสี Coating Thickness Gauge PTG-3725(Phase ll)  เครื่องวัดความหนาสี Coating Thickness Gauge PTG-4000(Phase ll) เครื่องวัดความหนาสี Coating Thickness Gauge PTG-4000(Phase ll)  เครื่องวัดความหนาสี Coating Thickness Gauge TT-260 เครื่องวัดความหนาสี Coating Thickness Gauge TT-260  เครื่องวัดความหนาสี Coating Thickness Gauge TM-520FN เครื่องวัดความหนาสี Coating Thickness Gauge TM-520FN  เครื่องวัดความหนาสี Coating Thickness ITK-MK04 เครื่องวัดความหนาสี Coating Thickness ITK-MK04  เครื่องวัดการยึดเกาะสี Pull-Off Adhesion Testers AT Series เครื่องวัดการยึดเกาะสี Pull-Off Adhesion Testers AT Series  เครื่องวัดความหนาสี Coating Thickness Gauge DC-3000FX เครื่องวัดความหนาสี Coating Thickness Gauge DC-3000FX  เครื่องวัดความหนาสี Coating Thickness Gauge ITK-Minitest-650B เครื่องวัดความหนาสี Coating Thickness Gauge ITK-Minitest-650B  เครื่องวัดความหนาสี Coating Thickness Gauge ITK-Minitest-650 เครื่องวัดความหนาสี Coating Thickness Gauge ITK-Minitest-650  เครื่องวัดความหนาสี Coating Thickness Gauge ITK-G8202 เครื่องวัดความหนาสี Coating Thickness Gauge ITK-G8202  เครื่องวัดความหนาสี Coating Thickness Gauge ITK-G8102 เครื่องวัดความหนาสี Coating Thickness Gauge ITK-G8102  เครื่องวัดความหนาสี Coating Thickness Gauge TM-550 FN เครื่องวัดความหนาสี Coating Thickness Gauge TM-550 FN  Wet Film Comb Coating Thickness Tester Meter เครื่องวัดความหนาสีแบบเปียก CM-8000 Wet Film Comb Coating Thickness Tester Meter เครื่องวัดความหนาสีแบบเปียก CM-8000  Wet Film Comb Coating Thickness Tester Meter เครื่องวัดความหนาสีแบบเปียก Wet Film Comb Coating Thickness Tester Meter เครื่องวัดความหนาสีแบบเปียก  Ultrasonic thickness gauge TM510FN Ultrasonic thickness gauge TM510FN  เครื่องวัดความหนาสี,POSIPEN เครื่องวัดความหนาสี,POSIPEN  เครื่องวัดความหนาสี สำหรับ Galvanizing,Metalizing on steel เครื่องวัดความหนาสี สำหรับ Galvanizing,Metalizing on steel  เครื่องวัดความหนาสี Coating Thickness Gauge Positector-6000 เครื่องวัดความหนาสี Coating Thickness Gauge Positector-6000  เครื่องวัดความหนาสี Coating Thickness Gauge CM8856 เครื่องวัดความหนาสี Coating Thickness Gauge CM8856  เครื่องวัดความหนาสี Coating Thickness Gauge CM8821 F เครื่องวัดความหนาสี Coating Thickness Gauge CM8821 F  เครื่องวัดความหนาสี Coating Thickness Gauge CM8822 FN เครื่องวัดความหนาสี Coating Thickness Gauge CM8822 FN  เครื่องวัดความหนาสี Coating Thickness Gauge SWT8000 เครื่องวัดความหนาสี Coating Thickness Gauge SWT8000  เครื่องวัดความหนาสี Coating Thickness Gauge IPX-201FN เครื่องวัดความหนาสี Coating Thickness Gauge IPX-201FN |