|

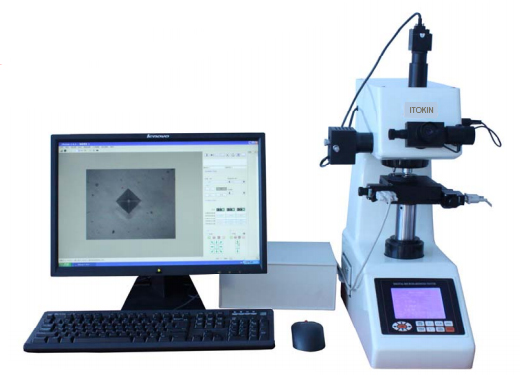

| เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester ITK-VKHV3 เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester ITK-VKHV3 Automatic Measuring System

Specification 1, Digital Micro Vickers/ Vicker Hardness Tester 2, Vickers Measuring software 3, Image system( CCD, image card) 4, Automatic control work X-Y stage 5, Automatic focusing, Z axis automatically up and down

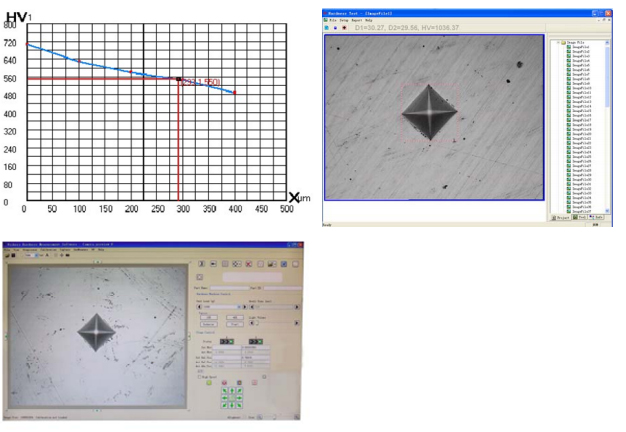

Feature: This instrument is widely used in such fields as metallurgy, electro-mechanics and mould, etc. It can analyze and measure the hardness value of specimen or surface hardened layers, hence it is an absolutely indispensable instrument for analysis and test in the field of mechanics machining or measurement of high precision parts. By means of RS232 interface to connect with computer, move X axis and Y axis with different step length selected, automatic focusing by Z axis, the instrument is specially fit to measure the hardness value of carburized layer of specimen or the depth of hardened layer. Applying with different loads, different kinds of specimens can be tested. And it can form and store the graph-text reports. It is simple to operate and easy to use for clients. This software can control such operations of hardness tester as: rotation of motorized turret, light luminosity, dwell time, movement of loading table, application of loading and automatic focusing, etc, it can enable the PC computer to control the hardness tester with command as well. At the same time, the hardness tester can feedback the information of command executed. It enables all the connecting units to communicate with each other. With friendly user interface, humanization, stability, reliability and very high precision position of mechanics, this software will completely meet the needs of test requirements. This instrument can not only test single-point of Vickers hardness indentation, but also can test continuous multi-point of Vickers hardness indentations after automatically loadings. And it can make out the curve of hardness distribution as well. Accordingly to this curve, the accordance depth of hardened layer can be calculated out. All the measuring data, calculating results and indentation images may form graph-text reports which can be printed out or stored. Technical Specifications: 1. Computer: Lenovo computer (2G memory, 500G hard disk, 19 inch LCD screen) 2. Ink jet printer 3. Operating system: WIN XP、WIN7 4. Digital imaging system High resolution: 130 million pixel(1280×1024) High speed acquisition: 1280×1024 resolution: 25 FPS

HARDNESS TESTER High definition: Black and white images and clarity is better. Target surface size: 1/2 inch 5. X-Y automatic test table Table size: 100×100×50 mm Maximum travel: 50×50 mm Minimum step: Less than 1μm Movement speed: Adjustable Control mode: Manual control, electric control, computer control 6. X-Y test table - computer control mode Location movement: The test table directly moves to the software settings; Point movement: Select any point of the sample, moved to the below of the indenter; Directional movement: Click the eight directions to make the test table move and the moving step can be set up; Arbitrary movement: Click any directions to make the test table move and make it easy for users to browse the specimen surface; Variable speed movement: There are two speeds (fast and slow) when moving the test table and the speed is optional and adjustable; Other function: Original position arbitrary setting, automatic reset, mechanical limit, and other professional features to meet various requirements. 7. Measuring method Automatic mode——Automatic test table moving (X, Y, Z direction) + automatic reading Manual mode 1——Automatic loading + manual eyepiece scribed line measurement Manual mode 2——Manual test table moving + manual focus + Automatic / manual measurement 8. Automatic / manual reading Automatic reading time: Single indentation reading time is about 300 milliseconds; Automatic measurement precision: 0.1μm; Automatic measurement repeatability: ±0.8% Manual reading: Manual pick, automatic search points, 4 points measurement, 2 diagonal measurement 9. Results save / output Save / output measurement data and experimental parameters, including D1,D2,HV,X,Y etc.; Save / output effective hardening layer depth curve report; Save / output image. Standard accessories: Digital Micro Vickers/ Vicker Hardness Tester 1set Computer (Lenovo, Hard disk: 500G, Memory: 2G, 19 inch LCD screen) 1 set Ink Jet Printer 1 set CCD Camera 1 set 1.5× Adapter 1 pc USB Softdog 1 pc Control Cables 1 pc RS232 Cable 1 pc Motorized Test Table 1 pc Motorized Test Table Control Box 1 pc Measuring Software 1 pc Software

|

เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester รุ่น MVicky-10/50 (Mikrosize) เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester รุ่น MVicky-10/50 (Mikrosize)  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester รุ่น MVicky-1000 (Mikrosize) เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester รุ่น MVicky-1000 (Mikrosize)  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester รุ่น MVision-1/10/30/50 (Mikrosize) เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester รุ่น MVision-1/10/30/50 (Mikrosize)  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester รุ่น MVI-1000A Micro Vicker เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester รุ่น MVI-1000A Micro Vicker  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester รุ่น uVicky-1 Micro Vicker เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester รุ่น uVicky-1 Micro Vicker  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester รุ่น uVK-1 Auto-turret Micro Vicker เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester รุ่น uVK-1 Auto-turret Micro Vicker  Touch Screen Automatic Turret Digital Vickers Hardness Tester 7MHVS-50A (AETALL) Touch Screen Automatic Turret Digital Vickers Hardness Tester 7MHVS-50A (AETALL)  Touch Screen Automatic Turret Digital Vickers Hardness Tester 7MHVS-50 (AETALL) Touch Screen Automatic Turret Digital Vickers Hardness Tester 7MHVS-50 (AETALL)  Touch Screen Automatic Turret Digital Vickers Hardness Tester 7MHVS-30A (AETALL) Touch Screen Automatic Turret Digital Vickers Hardness Tester 7MHVS-30A (AETALL)  Touch Screen Automatic Turret Digital Vickers Hardness Tester 7MHVS-30 (AETALL) Touch Screen Automatic Turret Digital Vickers Hardness Tester 7MHVS-30 (AETALL)  Touch Screen Automatic Turret Digital Vickers Hardness Tester 7MHVS-10A (AETALL) Touch Screen Automatic Turret Digital Vickers Hardness Tester 7MHVS-10A (AETALL)  Touch Screen Automatic Turret Digital Vickers Hardness Tester 7MHVS-10 (AETALL) Touch Screen Automatic Turret Digital Vickers Hardness Tester 7MHVS-10 (AETALL)  Touch Screen Automatic Turret Digital Vickers Hardness Tester 7MHVS-5A (AETALL) Touch Screen Automatic Turret Digital Vickers Hardness Tester 7MHVS-5A (AETALL)  Touch Screen Manual Turret Digital Vickers Hardness Tester 7MHVS-5 (AETALL) Touch Screen Manual Turret Digital Vickers Hardness Tester 7MHVS-5 (AETALL)  Manual Turret Vickers Hardness Tester HV-50A (AETALL) Manual Turret Vickers Hardness Tester HV-50A (AETALL)  Manual Turret Vickers Hardness Tester HV-50 (AETALL) Manual Turret Vickers Hardness Tester HV-50 (AETALL)  Automatic Turret Vickers Hardness Tester HV-30A (AETALL) Automatic Turret Vickers Hardness Tester HV-30A (AETALL)  Manual Turret Vickers Hardness Tester HV-30 (AETALL) Manual Turret Vickers Hardness Tester HV-30 (AETALL)  Automatic Turret Vickers Hardness Tester HV-10A (AETALL) Automatic Turret Vickers Hardness Tester HV-10A (AETALL)  Manual Turret Vickers Hardness Tester HV-10 (AETALL) Manual Turret Vickers Hardness Tester HV-10 (AETALL)  Automatic Turret Vickers Hardness Tester HV-5A (AETALL) Automatic Turret Vickers Hardness Tester HV-5A (AETALL)  Manual Turret Vickers Hardness Tester HV-5 (AETALL) Manual Turret Vickers Hardness Tester HV-5 (AETALL)  Digital Vickers Hardness Tester HVS-10 Manual Turret (AETALL) Digital Vickers Hardness Tester HVS-10 Manual Turret (AETALL)  XHVT-1000Z Intelligent Micro Vickers Hardness Tester XHVT-1000Z Intelligent Micro Vickers Hardness Tester  HV-1000 Series Micro Vickers Hardness Tester (SH-TEST) HV-1000 Series Micro Vickers Hardness Tester (SH-TEST)  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester รุ่น HVS-1000TA X-Y เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester รุ่น HVS-1000TA X-Y  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester รุ่น HVS-1000TA เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester รุ่น HVS-1000TA  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester รุ่น 200HVS-5TA-10TA-30TA-50TA เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester รุ่น 200HVS-5TA-10TA-30TA-50TA  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester รุ่น 300HVS-5TA-10TA-30TA-50TA เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester รุ่น 300HVS-5TA-10TA-30TA-50TA  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester รุ่น 300HVS-1000TA เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester รุ่น 300HVS-1000TA  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester SHVS-5011M (SUNPOC) เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester SHVS-5011M (SUNPOC)  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester SHVS-5011 (SUNPOC) เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester SHVS-5011 (SUNPOC)  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester TB-MCV-1 (NOVOTEST) เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester TB-MCV-1 (NOVOTEST)  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester VMT-X Series (Matsuzawa) เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester VMT-X Series (Matsuzawa)  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester MMT-X Series (Matsuzawa) เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester MMT-X Series (Matsuzawa)  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester VIA (Highwood) เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester VIA (Highwood)  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester 900-398 (Phase ll) เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester 900-398 (Phase ll)  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester 900-392 (Phase ll) เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester 900-392 (Phase ll)  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester 900-391 (Phase ll) เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester 900-391 (Phase ll)  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester 900-390 (Phase ll) เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester 900-390 (Phase ll)  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester HVT-5 เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester HVT-5  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester MVT-1000 เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester MVT-1000  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester SMV-2000MZ เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester SMV-2000MZ  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester SMV-404 เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester SMV-404  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester SMV-402 เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester SMV-402  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester ITK-VKHV2 เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester ITK-VKHV2  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester ITK-VKHV1 เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester ITK-VKHV1  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester ITK-500M เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester ITK-500M  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester XVick-S709 เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester XVick-S709  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester IVick-478H เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester IVick-478H  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester XVick-S504 เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester XVick-S504  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester XVick-501 เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester XVick-501  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester SMV-1000 เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester SMV-1000  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester SHV 500M เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester SHV 500M  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester HWDV-7 (Higwood) เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester HWDV-7 (Higwood)  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester HWDM (Highwood) เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester HWDM (Highwood)  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester SHVS-500 เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester SHVS-500  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester SMV-1000Z เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester SMV-1000Z  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester SMV-1000X เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester SMV-1000X  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester SMV-1000SZ เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester SMV-1000SZ  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester SHV-1000MZ เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester SHV-1000MZ |