|

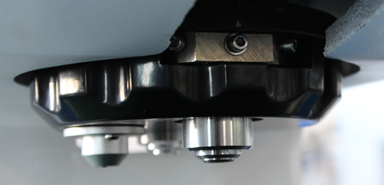

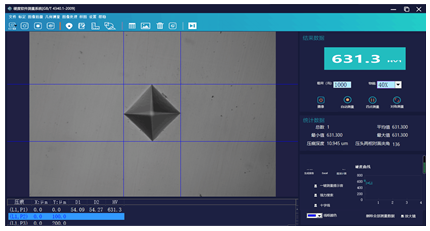

| Manual Turret Vickers Hardness Tester HV-50 (AETALL) Manual Turret Vickers Hardness Tester HV-50 (AETALL) HV-50 ส่วนใหญ่จะใช้สำหรับการวัดความแข็งของ Vickers ของโลหะต่างๆ และวัสดุที่ไม่ใช่โลหะบางชนิด สามารถใช้วัดความแข็งของชิ้นส่วนที่ผ่านการบำบัดด้วยความร้อน ฯลฯ นอกจากนี้ยังเหมาะสำหรับการคาร์บอไนเซชัน ความลึกที่มีประสิทธิภาพในการดับชั้นชุบแข็ง ชั้นเคลือบผิว การเคลือบผิว และชิ้นส่วนเชื่อมที่ได้รับผลกระทบจากความร้อน

Specification

Product advantages

Packing List

|

เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester รุ่น MVicky-10/50 (Mikrosize) เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester รุ่น MVicky-10/50 (Mikrosize)  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester รุ่น MVicky-1000 (Mikrosize) เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester รุ่น MVicky-1000 (Mikrosize)  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester รุ่น MVision-1/10/30/50 (Mikrosize) เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester รุ่น MVision-1/10/30/50 (Mikrosize)  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester รุ่น MVI-1000A Micro Vicker เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester รุ่น MVI-1000A Micro Vicker  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester รุ่น uVicky-1 Micro Vicker เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester รุ่น uVicky-1 Micro Vicker  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester รุ่น uVK-1 Auto-turret Micro Vicker เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester รุ่น uVK-1 Auto-turret Micro Vicker  Touch Screen Automatic Turret Digital Vickers Hardness Tester 7MHVS-50A (AETALL) Touch Screen Automatic Turret Digital Vickers Hardness Tester 7MHVS-50A (AETALL)  Touch Screen Automatic Turret Digital Vickers Hardness Tester 7MHVS-50 (AETALL) Touch Screen Automatic Turret Digital Vickers Hardness Tester 7MHVS-50 (AETALL)  Touch Screen Automatic Turret Digital Vickers Hardness Tester 7MHVS-30A (AETALL) Touch Screen Automatic Turret Digital Vickers Hardness Tester 7MHVS-30A (AETALL)  Touch Screen Automatic Turret Digital Vickers Hardness Tester 7MHVS-30 (AETALL) Touch Screen Automatic Turret Digital Vickers Hardness Tester 7MHVS-30 (AETALL)  Touch Screen Automatic Turret Digital Vickers Hardness Tester 7MHVS-10A (AETALL) Touch Screen Automatic Turret Digital Vickers Hardness Tester 7MHVS-10A (AETALL)  Touch Screen Automatic Turret Digital Vickers Hardness Tester 7MHVS-10 (AETALL) Touch Screen Automatic Turret Digital Vickers Hardness Tester 7MHVS-10 (AETALL)  Touch Screen Automatic Turret Digital Vickers Hardness Tester 7MHVS-5A (AETALL) Touch Screen Automatic Turret Digital Vickers Hardness Tester 7MHVS-5A (AETALL)  Touch Screen Manual Turret Digital Vickers Hardness Tester 7MHVS-5 (AETALL) Touch Screen Manual Turret Digital Vickers Hardness Tester 7MHVS-5 (AETALL)  Manual Turret Vickers Hardness Tester HV-50A (AETALL) Manual Turret Vickers Hardness Tester HV-50A (AETALL)  Automatic Turret Vickers Hardness Tester HV-30A (AETALL) Automatic Turret Vickers Hardness Tester HV-30A (AETALL)  Manual Turret Vickers Hardness Tester HV-30 (AETALL) Manual Turret Vickers Hardness Tester HV-30 (AETALL)  Automatic Turret Vickers Hardness Tester HV-10A (AETALL) Automatic Turret Vickers Hardness Tester HV-10A (AETALL)  Manual Turret Vickers Hardness Tester HV-10 (AETALL) Manual Turret Vickers Hardness Tester HV-10 (AETALL)  Automatic Turret Vickers Hardness Tester HV-5A (AETALL) Automatic Turret Vickers Hardness Tester HV-5A (AETALL)  Manual Turret Vickers Hardness Tester HV-5 (AETALL) Manual Turret Vickers Hardness Tester HV-5 (AETALL)  Digital Vickers Hardness Tester HVS-10 Manual Turret (AETALL) Digital Vickers Hardness Tester HVS-10 Manual Turret (AETALL)  XHVT-1000Z Intelligent Micro Vickers Hardness Tester XHVT-1000Z Intelligent Micro Vickers Hardness Tester  HV-1000 Series Micro Vickers Hardness Tester (SH-TEST) HV-1000 Series Micro Vickers Hardness Tester (SH-TEST)  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester รุ่น HVS-1000TA X-Y เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester รุ่น HVS-1000TA X-Y  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester รุ่น HVS-1000TA เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester รุ่น HVS-1000TA  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester รุ่น 200HVS-5TA-10TA-30TA-50TA เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester รุ่น 200HVS-5TA-10TA-30TA-50TA  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester รุ่น 300HVS-5TA-10TA-30TA-50TA เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester รุ่น 300HVS-5TA-10TA-30TA-50TA  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester รุ่น 300HVS-1000TA เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester รุ่น 300HVS-1000TA  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester SHVS-5011M (SUNPOC) เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester SHVS-5011M (SUNPOC)  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester SHVS-5011 (SUNPOC) เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester SHVS-5011 (SUNPOC)  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester TB-MCV-1 (NOVOTEST) เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester TB-MCV-1 (NOVOTEST)  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester VMT-X Series (Matsuzawa) เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester VMT-X Series (Matsuzawa)  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester MMT-X Series (Matsuzawa) เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester MMT-X Series (Matsuzawa)  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester VIA (Highwood) เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester VIA (Highwood)  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester 900-398 (Phase ll) เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester 900-398 (Phase ll)  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester 900-392 (Phase ll) เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester 900-392 (Phase ll)  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester 900-391 (Phase ll) เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester 900-391 (Phase ll)  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester 900-390 (Phase ll) เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester 900-390 (Phase ll)  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester HVT-5 เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester HVT-5  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester MVT-1000 เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester MVT-1000  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester SMV-2000MZ เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester SMV-2000MZ  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester SMV-404 เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester SMV-404  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester SMV-402 เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester SMV-402  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester ITK-VKHV3 เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester ITK-VKHV3  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester ITK-VKHV2 เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester ITK-VKHV2  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester ITK-VKHV1 เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester ITK-VKHV1  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester ITK-500M เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester ITK-500M  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester XVick-S709 เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester XVick-S709  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester IVick-478H เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester IVick-478H  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester XVick-S504 เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester XVick-S504  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester XVick-501 เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester XVick-501  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester SMV-1000 เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester SMV-1000  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester SHV 500M เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester SHV 500M  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester HWDV-7 (Higwood) เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester HWDV-7 (Higwood)  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester HWDM (Highwood) เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester HWDM (Highwood)  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester SHVS-500 เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester SHVS-500  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester SMV-1000Z เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester SMV-1000Z  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester SMV-1000X เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester SMV-1000X  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester SMV-1000SZ เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester SMV-1000SZ  เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester SHV-1000MZ เครื่องทดสอบความแข็งโลหะ Vicker Hardness Tester SHV-1000MZ |