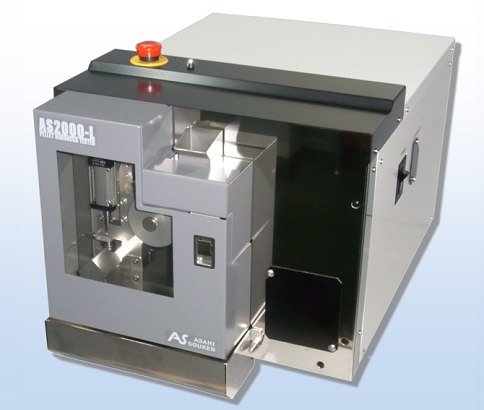

Pallet Hardness Tester

AS2000-L

ASAHI SOUKEN

The Pellet Hardness tester AS2000-L is measures hardness of the spherical granulation (pellet) such as carbon

black

Measurement data is displayed for the PC, and totalizauon data is possible to output from the printer.

It conforms to ISO 8942, ASTM D5230.

| Item |

Specifications |

Remarks |

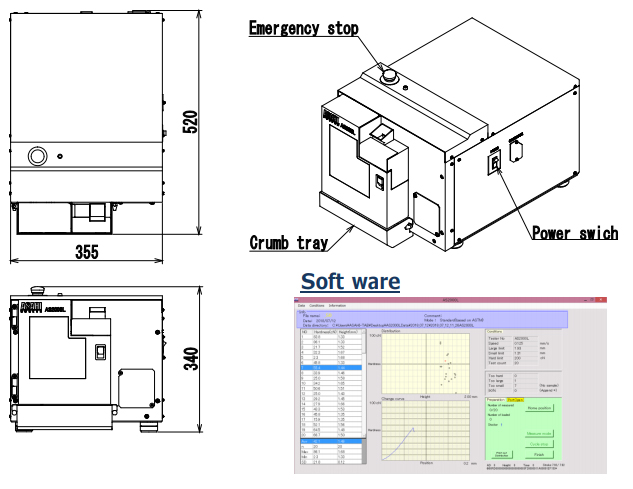

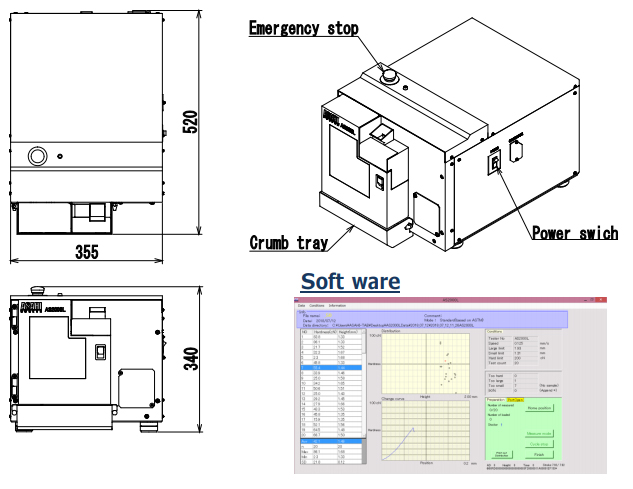

| Dimensions |

W355 x D520 x H340 (mm) |

|

| Weight |

Approximately 25kg |

|

| Maximum force |

200cN |

|

| Press speed |

Default 0.125mm/sec |

Settings can be changed |

| Pellet size |

1.0mm to 1.7mm |

|

| Output |

USB Type-B |

For Data Transfer to PC |

| Power supply |

AC100V±5% |

For 50/60Hz common use |

| Supporting OS |

Windows 7 〜 Windows 10 |

|

External dimensions

| Measurementsample |

Sample saze |

0.8-2.0mm |

Maximum number of

pieces |

100 piece |

| Alarn function |

Indication |

Error massage only (not buzzer) |

| LoadmeasJrementunit |

Maximum load |

200.0cN |

| Measurement Accuritcy |

+ 0.2% of the maximum load |

| Meisurement systern |

Load cell |

| lnterface |

USB Type-B |

| General specification |

Power supply |

AC100-240V +-5% 50/60Hz |

| Povver consumption |

Maximum 90W |

| Use enMronment |

Temperature: 18-28C humidity: 40-70% (No condensation) |

| Outside dimension; Weight |

Dimensions: 355mm (W) x520mm(D) x 340rnm(H) Weight: approx 25 kg |

| Accessories |

Power cable |

1 |

| Communication cable |

1 |

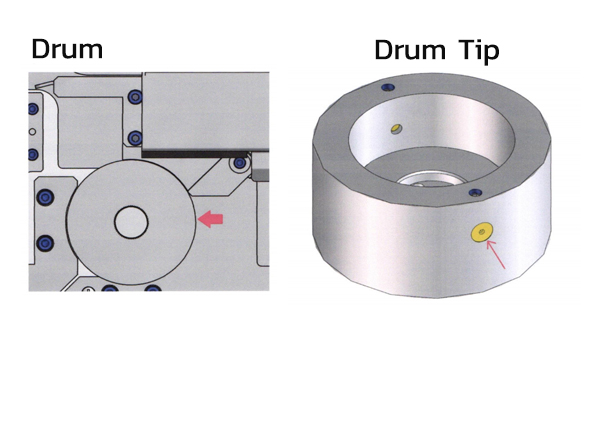

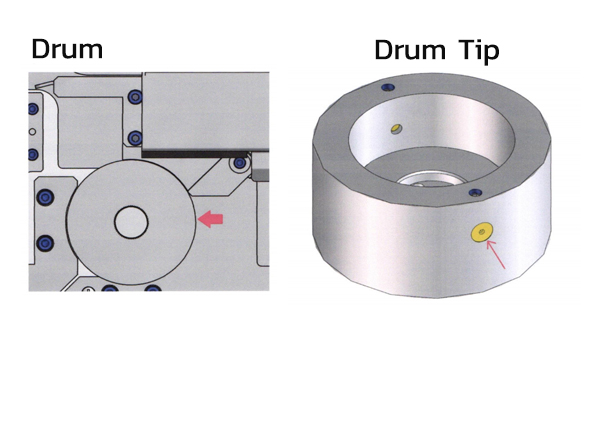

| Feed drum |

2 |

| calibration Jig |

Ceramic Aage(lmm) :1, weight(100g) :1 |

| Cleaning brush |

1 |

| Instruction manual |

1 (this book) |

Fast measurement

Compared with the conventional model, the measurement lead time has been reduced to about half.

*about 10 - 15 sec/piece (depend on the conditions)

Hardness and pellet size measurement of spherical sample

Simultaneous measurement of hardness and the pellet size of the granulation properties of the carbon black.

High Precision

Improve the measurement accuracy by the adoption of the Z-axis actuator

Two data management

You can store two types of data: pellet size distribution chart and individual load curve data.

*Data format is CSV

Safety Device

Starting is possible only if the cover is equipped.

Measurement condition

It corresponds to measurement conditions of ASTM standard, and can be called with one touch.

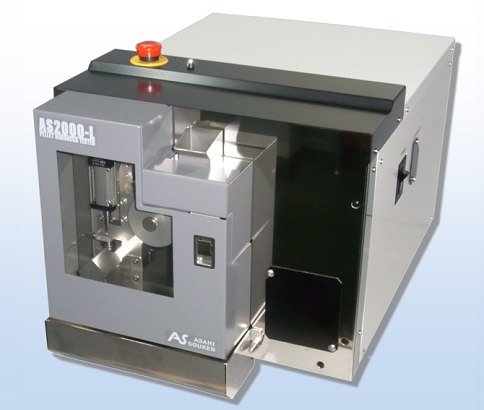

Pallet Hardness Tester AS2000-C

Pallet Hardness Tester AS2000-C