เครื่องวัดความแข็งพกพา

Portable Hardness Tester Model PHT-330-350 SUNPOC

สอบถามสินค้าได้ที่ 02-9744354-6 สายด่วน 088-7777277

Line : @itokin2000.com

Email : salesitokin@gmail.com

ดาวน์โหลด

|

|

|

| รุ่น PHT-330 |

รุ่น PHT-350 |

| |

|

รูปภาพประกอบสำหรับ รุ่น PHT-330

PHT-330 Leeb Hardness Tester

Main application:

Use for testing die cavity of molds, bearings and other parts, failure analysis of pressure vessel, steam generator and other equipment, heavy work piece, the installed machinery and permanently assembled parts, testing surface of a small hollow space, material identification in the warehouse of metallic materials, rapid testing in large range and multi-measuring areas for large-scale work piece.

Feature:

1. Support "forged steel (Steel)" material, when using the D/DC impact device test "forged" sample, can read HB value directly, without the need for manual checking table.

2. Wide measuring range. It can measure the hardness of all metallic materials. Direct display of hardness scales HRA, HRB, HRC, HV, HS, HL, HB and three types of strength values immediately.

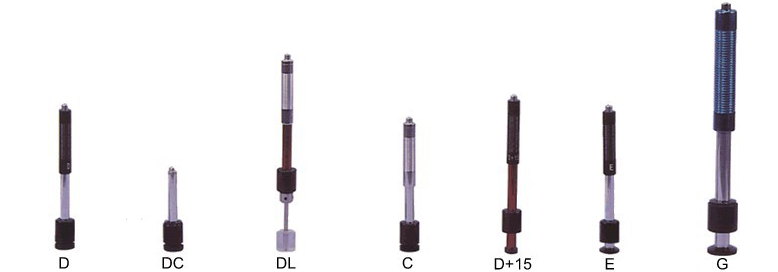

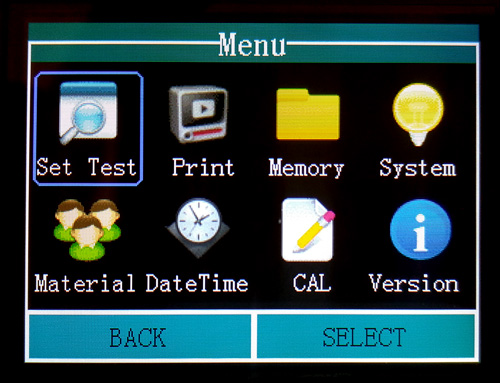

3. Seven impact devices are available for special application. Automatically identify the type of impact devices.

4. Upper and lower limit can be preset. It will alarm automatically when the result value exceeding the limit.

5. Battery information indicates the rest capacity of the battery and the charge status.

6. User calibration function.

7. USB port with the PC humanity multi-functions data proceeding software.

8. Original imported high speed thermal printer support the immediate printing function. It can save data permanently.

9. Auto power off to save energy.

10. Industrialized housing design, sturdy, compact, portable, high reliability, suitable for harsh operating environment, vibration, shock and electromagnetic interference.

11. Excellent after-sale service system for high quality products---two years’ guarantee and all life maintenance. Easy to buy and comfortable to use.

Technical specifications:

|

Measuring range

|

HLD(170-960), HB (19-683),HV (80-1042),HS (30.6-102.6),

HRA(59.1-88),HRB (13.5-101.7), HRC (17.9-69.5)

|

|

Measuring direction

|

360°

|

|

Indication Error

|

±6HLD (D impact device)

|

|

Hardness Scale

|

HRA , HRB, HRC, HV, HS, HL, HB

|

|

Display

|

dot matrix LCD,128×64 dots, with printer

|

|

Data memory

|

600 groups max.(relative to impact times 32~1)

|

|

Printing paper

|

(57.5±0.5)mm, diameter is 30mm

|

|

Battery pack

|

6V NI-MH Battery charger: 9V/500mA.

|

|

Continuous working period

|

about 200hours(With backlight off, no printing)

|

|

Communication interface

|

USB2.0

|

|

Dimensions

|

210 x 85 x 45mm

|

|

Weight

|

about 0.6kg pack weight: 5.2kg

|

1 SET

|

No.

|

Item

|

Q'ty

|

No.

|

Item

|

Q'ty

|

|

1

|

Main Unit

|

1 pc

|

7

|

Paper for printing

|

1 pc

|

|

2

|

D type impact device

|

1 pc

|

8

|

Manual

|

1 pc

|

|

3

|

Standard test block

|

1 pc

|

9

|

Warranty card

|

1 pc

|

|

4

|

Cleaning brush (I)

|

1 pc

|

10

|

Data Pro software

|

1 pc

|

|

5

|

Small support ring

|

1 pc

|

11

|

Communication cable

|

1 pc

|

|

6

|

Battery Charger

|

1 pc

|

12

|

Instrument case

|

1 pc

|

PHT-350 Leeb Hardness Tester( colour screen)

Main application:

It is suitable for Steel and cast steel, alloy steel, stainless steel, gray cast iron, nodular cast iron, cast aluminum alloy, copper zinc alloy (brass), copper alloy (bronze), tin pure copper, forging steel etc.

Feature:

the PHT-350 hardness tester is an innovative improvement about hardness measurement mechanism and circuit performance based on leeb hardness measuring instrument product. Portable, flexible replacement and suitable for the job site, field operations

- Color screen, hardness scale dual display and optional.

- Add function - custom material

- Built-in high speed thermal printer, support immediately printing

function. It can save data permanently.

- Support probe hot-plugging.

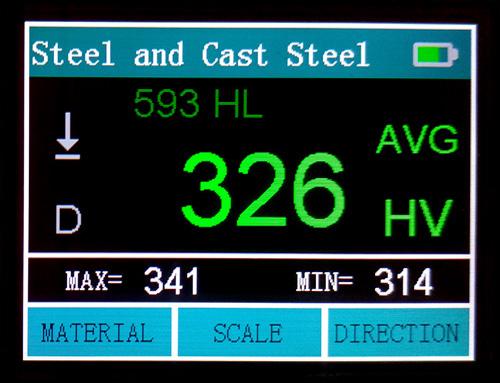

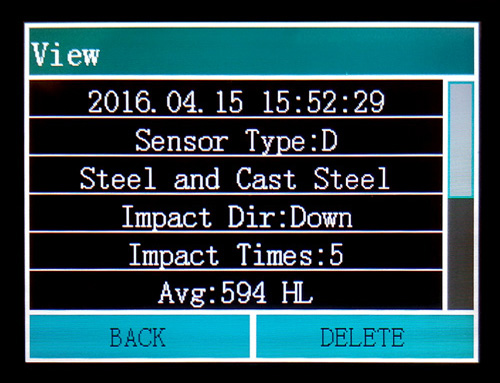

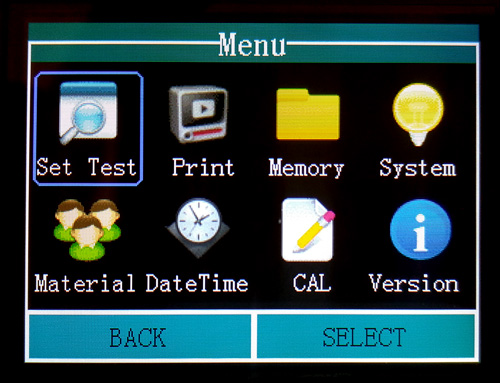

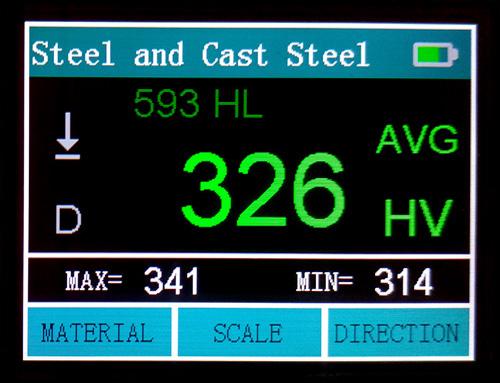

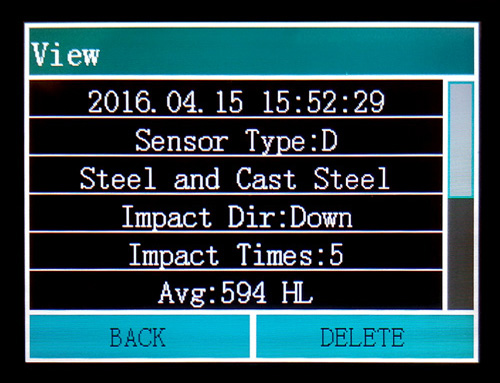

รูปภาพประกอบสำหรับรุ่น PHT-350

.jpg) |

|

|

|

|

|

| หน้าจอแสดงผลการวัด |

หน้าต่างการอ่านค่า |

หน้าจอเมนู |

Technical specifications:

|

Measuring range

|

HLD (170-960), HB (19-683), HV (80-1042), HS (30.6-110),

HRA(59.1-88), HRB (13.5-101.7), HRC (17.9-69.5)

|

|

Measuring direction

|

360°

|

|

Indication Error

|

±6HLD (D impact device)

|

|

Hardness Scale

|

HRA , HRB, HRC, HV, HS, HL, HB

|

|

Display

|

320*240mm Color LCD, two hardness scale dual-display. with Bulit-in Printer

|

|

Data memory

|

600 groups max.(relative to impact times 32~1)

|

|

Printing paper

|

width is (57.5±0.5)mm, diameter is 30mm

|

|

Battery pack

|

7.4V Li-battery

|

|

Continuous working period

|

about 200hours (With backlight off, no printing)

|

|

Communication interface

|

USB2.0

|

|

Dimensions

|

210 x 85 x 45mm

|

|

Weight

|

about 0.6kg pack weight: 5.2kg

|

Standard accessories:

|

No.

|

Item

|

Q'ty

|

No.

|

Item

|

Q'ty

|

|

1

|

PHT350 Main body

|

1 pc

|

7

|

Paper for printing

|

1pc

|

|

2

|

D type impact device

|

1 pc

|

8

|

Manual

|

1pc

|

|

3

|

Standard test block

|

1 pc

|

9

|

Warranty card

|

1 pc

|

|

4

|

Cleaning brush

|

1 pc

|

10

|

Data Pro software

|

1 pc

|

|

5

|

Small supporting ring

|

1 pc

|

11

|

Communication cable

|

1 pc

|

|

6

|

Battery charger

|

1 pc

|

12

|

Instrument box

|

1 pc

|

|

|

|

Type of Impact Device

|

DC(D)/DL

|

C

|

D+15

|

E

|

G

|

|

Application

|

DC type used to hole or inside face of cylinder,

DL type used to elongated narrow slot or hole, D type for routine measurements.

|

Suitable for measuring surface of the trench or concave.

|

Suitable for measuring thin workpiece and harden surface.

|

Suitable for heavy or rough castings and forgings.

|

Suitable high hardness material.

|

|

Impacting energy

|

11mJ

|

2.7mJ

|

11mJ

|

11mJ

|

90mJ

|

|

Mass of impact body

|

5.5g/7.2g

|

3.0g

|

7.8g

|

5.5g

|

20.0g

|

|

Test tip hardness:

|

1600HV

|

1600HV

|

1600HV

|

5000HV

|

1600HV

|

|

Dia. Test tip:

|

3mm

|

3mm

|

3mm

|

3mm

|

5mm

|

|

Material of test tip:

|

Tungsten carbide

|

Tungsten carbide

|

Tungsten carbide

|

synthetic diamond

|

Tungsten carbide

|

|

Impact device diameter:

|

20mm

|

20mm

|

20mm

|

20mm

|

30mm

|

|

Impact device length:

|

86(147)/75mm

|

141mm

|

162mm

|

155mm

|

254mm

|

|

Impact device weight:

|

50g

|

75g

|

80g

|

80g

|

250g

|

|

Max. hardness of sample

|

940HV

|

1000HV

|

940HV

|

1200HV

|

650HB

|

|

roughness of sample

|

Ra 1.6μm

|

Ra 0.4μm

|

Ra 1.6μm

|

Ra 1.6μm

|

Ra 6.3μm

|

|

Min. weight of sample:

|

>5kg

|

>1.5kg

|

>5kg

|

>5kg

|

>15kg

|

|

Measure directly with stand

|

2~5kg

|

0.5~1.5kg

|

2~5kg

|

2~5kg

|

5~15kg

|

|

Need coupling tightly

|

0.05~2kg

|

0.02~0.5kg

|

0.05~2kg

|

0.05~2kg

|

0.5~5kg

|

|

Min. thickness of sample

|

5mm

|

1mm

|

5mm

|

5mm

|

10mm

|

|

layer thickness hardening:

|

≥0.8mm

|

≥0.2mm

|

≥0.8mm

|

≥0.8mm

|

≥1.2mm

|

|

Indentation size:

|

|

Type of Impact Device

|

DC(D)/DL

|

C

|

D+15

|

E

|

G

|

|

Hardness 300HV

|

Indentation diameter:

|

0.54mm

|

0.54mm

|

0.38mm

|

1.03mm

|

0.54mm

|

|

Depth of indentation:

|

24μm

|

24μm

|

12μm

|

53μm

|

24μm

|

|

Hardness 600HV

|

Indentation diameter:

|

0.54mm

|

0.54mm

|

0.32mm

|

0.90mm

|

0.54mm

|

|

Depth of indentation

|

17μm

|

17μm

|

8μm

|

41μm

|

17μm

|

|

Hardness 800HV

|

Indentation diameter:

|

0.35mm

|

0.35mm

|

0.35mm

|

--

|

0.35mm

|

|

Depth of indentation

|

10μm

|

10μm

|

7μm

|

--

|

10μm

|

เครื่องวัดความแข็ง แบบพกพา Portable Hardness Tester model THL-370

เครื่องวัดความแข็ง แบบพกพา Portable Hardness Tester model THL-370  เครื่องวัดความแข็ง แบบพกพา Portable Hardness Tester model THL-360

เครื่องวัดความแข็ง แบบพกพา Portable Hardness Tester model THL-360  เครื่องวัดความแข็ง แบบพกพา Portable Hardness Tester model THL-280 Plus

เครื่องวัดความแข็ง แบบพกพา Portable Hardness Tester model THL-280 Plus  เครื่องวัดความแข็ง แบบพกพา Portable Hardness Tester model THL280

เครื่องวัดความแข็ง แบบพกพา Portable Hardness Tester model THL280  เครื่องวัดความแข็ง แบบพกพา Portable Hardness Tester model REI-200

เครื่องวัดความแข็ง แบบพกพา Portable Hardness Tester model REI-200  เครื่องวัดความแข็ง แบบพกพา Portable Hardness Tester model REI-160

เครื่องวัดความแข็ง แบบพกพา Portable Hardness Tester model REI-160  เครื่องวัดความแข็ง แบบพกพา Portable Hardness Tester model REI-150

เครื่องวัดความแข็ง แบบพกพา Portable Hardness Tester model REI-150  เครื่องวัดความแข็ง แบบพกพา Portable Hardness Tester model REI-100

เครื่องวัดความแข็ง แบบพกพา Portable Hardness Tester model REI-100  เครื่องวัดความแข็ง แบบพกพา Portable Hardness Tester model HM-6561

เครื่องวัดความแข็ง แบบพกพา Portable Hardness Tester model HM-6561  เครื่องวัดความแข็ง แบบพกพา Portable Hardness Tester model DHT-300

เครื่องวัดความแข็ง แบบพกพา Portable Hardness Tester model DHT-300  เครื่องวัดความแข็ง แบบพกพา Portable Hardness Tester model HL-200

เครื่องวัดความแข็ง แบบพกพา Portable Hardness Tester model HL-200  เครื่องวัดความแข็ง แบบพกพา Portable Hardness Tester model ISH-PH

เครื่องวัดความแข็ง แบบพกพา Portable Hardness Tester model ISH-PH  เครื่องวัดความแข็ง แบบพกพา Portable Hardness Tester model HLJ-2100

เครื่องวัดความแข็ง แบบพกพา Portable Hardness Tester model HLJ-2100  เครื่องวัดความแข็ง แบบพกพา Portable Hardness Tester model HLN-200

เครื่องวัดความแข็ง แบบพกพา Portable Hardness Tester model HLN-200  เครื่องทดสอบความแข็ง แบบพกพา Portable Hardness model UCI-Leeb918

เครื่องทดสอบความแข็ง แบบพกพา Portable Hardness model UCI-Leeb918  เครื่องวัดความแข็ง แบบพกพา Portable Hardness Tester model iLeeb-210

เครื่องวัดความแข็ง แบบพกพา Portable Hardness Tester model iLeeb-210  เครื่องวัดความแข็ง แบบพกพา Portable Hardness Tester model iLeeb-300 Color Screen

เครื่องวัดความแข็ง แบบพกพา Portable Hardness Tester model iLeeb-300 Color Screen  เครื่องวัดความแข็ง แบบพกพา Portable Hardness Tester model iLeeb-150

เครื่องวัดความแข็ง แบบพกพา Portable Hardness Tester model iLeeb-150  เครื่องวัดความแข็ง แบบพกพา Portable Hardness Tester model ADL-DU110 (ADL)

เครื่องวัดความแข็ง แบบพกพา Portable Hardness Tester model ADL-DU110 (ADL)  เครื่องวัดความแข็งระบบอัลตร้าโซนิค Ultrasonic Hardness tester TM-U3 (TMTECK)

เครื่องวัดความแข็งระบบอัลตร้าโซนิค Ultrasonic Hardness tester TM-U3 (TMTECK)  เครื่องวัดความแข็ง แบบพกพา Portable Hardness Tester model ADL-D100 (ADL)

เครื่องวัดความแข็ง แบบพกพา Portable Hardness Tester model ADL-D100 (ADL)  เครื่องวัดความแข็ง แบบพกพา Portable Hardness Tester Leeb THL-600

เครื่องวัดความแข็ง แบบพกพา Portable Hardness Tester Leeb THL-600  เครื่องวัดความแข็ง Portable Hardness Tester Model PHT-340 SUNPOC

เครื่องวัดความแข็ง Portable Hardness Tester Model PHT-340 SUNPOC  เครื่องวัดความแข็ง Portable Hardness Tester Model PHT-190 SUNPOC

เครื่องวัดความแข็ง Portable Hardness Tester Model PHT-190 SUNPOC  เครื่องวัดความแข็ง แบบพกพา Portable Hardness Tester PHT-1700 (Phase ll)

เครื่องวัดความแข็ง แบบพกพา Portable Hardness Tester PHT-1700 (Phase ll)  เครื่องวัดความแข็ง แบบพกพา Portable Hardness Tester PHT-3500 (Phase ll)

เครื่องวัดความแข็ง แบบพกพา Portable Hardness Tester PHT-3500 (Phase ll)  เครื่องวัดความแข็ง แบบพกพา Portable Hardness Tester PHT-3300 (Phase ll)

เครื่องวัดความแข็ง แบบพกพา Portable Hardness Tester PHT-3300 (Phase ll)  เครื่องวัดความแข็ง แบบพกพา Portable Hardness Tester PHT-2100 (Phase ll)

เครื่องวัดความแข็ง แบบพกพา Portable Hardness Tester PHT-2100 (Phase ll)  เครื่องวัดความแข็ง แบบพกพา Portable Hardness Tester PHT-1900 (Phase ll)

เครื่องวัดความแข็ง แบบพกพา Portable Hardness Tester PHT-1900 (Phase ll)  เครื่องวัดความแข็ง แบบพกพา Portable Hardness Tester PHT-1800 (Phase ll)

เครื่องวัดความแข็ง แบบพกพา Portable Hardness Tester PHT-1800 (Phase ll)  เครื่องวัดความแข็ง แบบพกพา Portable Hardness Tester PHT-6000 (Phase ll)

เครื่องวัดความแข็ง แบบพกพา Portable Hardness Tester PHT-6000 (Phase ll)  เครื่องวัดความแข็ง แบบพกพา Portable Hardness Tester model THL-110 (Pen Type)

เครื่องวัดความแข็ง แบบพกพา Portable Hardness Tester model THL-110 (Pen Type)  เครื่องวัดความแข็ง แบบพกพา Portable Hardness Tester model THL-270

เครื่องวัดความแข็ง แบบพกพา Portable Hardness Tester model THL-270  เครื่องวัดความแข็ง แบบพกพา Portable Hardness Tester model THL210

เครื่องวัดความแข็ง แบบพกพา Portable Hardness Tester model THL210  เครื่องวัดความแข็งระบบอัลตร้าโซนิก Ultrasonic Hardness Gauge Model SH-21

เครื่องวัดความแข็งระบบอัลตร้าโซนิก Ultrasonic Hardness Gauge Model SH-21  เครื่องวัดความแข็งระบบอัลตร้าโซนิก Ultrasonic Hardness Gauge Model SU-100

เครื่องวัดความแข็งระบบอัลตร้าโซนิก Ultrasonic Hardness Gauge Model SU-100

.jpg)