Surface Roughness Tester แผ่นทดสอบความเรียบ

Model R2006 (PTE) Paint Test Equipment

ได้รับการรับรองตามมาตรฐานสากล Compliant to ISO 8503-1, ISO 8503-2 and ASTM D4417.

ดาวน์โหลด

แผ่นทดสอบความเรียบผิว รุ่น R2006 คุณภาพจาก ประเทศอังกฤษ Paint Test Equipment (PTE) ใช้สำหรับทดสอบความเรียบผิวของชิ้นงาน เพื่อตรวจสอบว่าชิ้นงาม นั้นๆ ตรงตรมวัตถุประสงค์หรือไม่ มีผิวขรุขระ ผิวหยาบ หรือไม่?

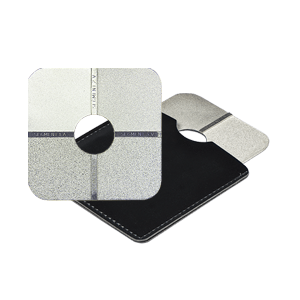

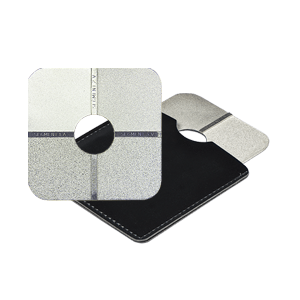

Surface Roughness แผ่นทดสอบความเรียบผิว รุ่น R2006

.png)

|

|

| แผ่นทดสอบความเรียบผิว |

โมเดล R2006 |

|

|

| มาพร้อมชุดจัดเก็บอุปกรณ์ |

คุณภาพจากประเทศอังกฤษ |

Product Description

Surface Roughness Comparator for grit-blast and shot-blast surface profile comparison measurement of blast-cleaned steel.

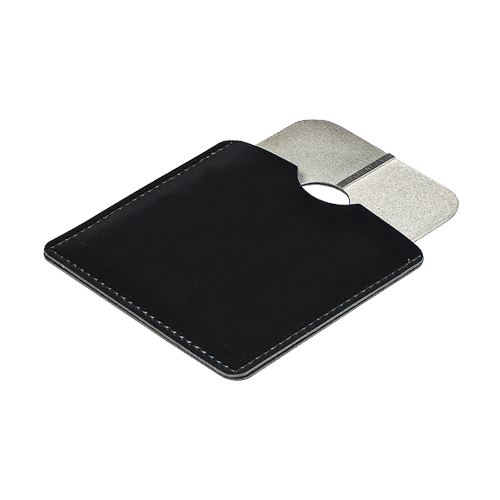

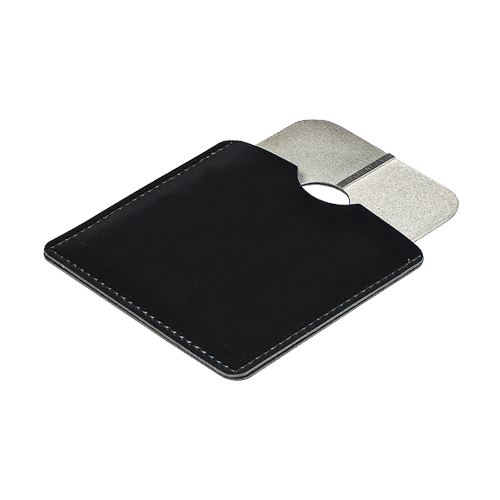

The Surface Roughness Comparator is supplied in a protective Wallet.

Compliant to ISO 8503-1, ISO 8503-2 and ASTM D4417.

Technical Specification

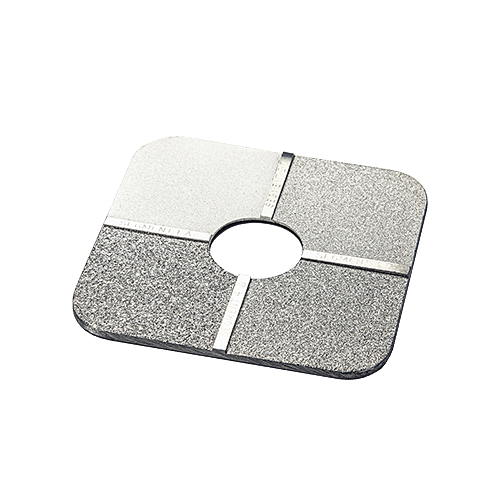

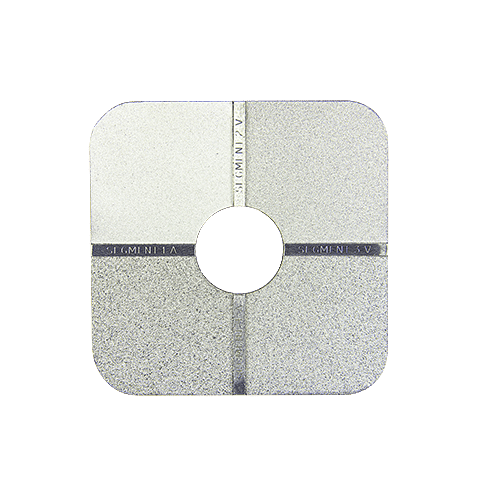

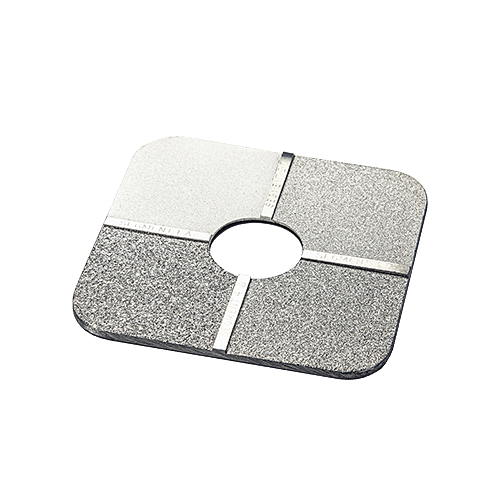

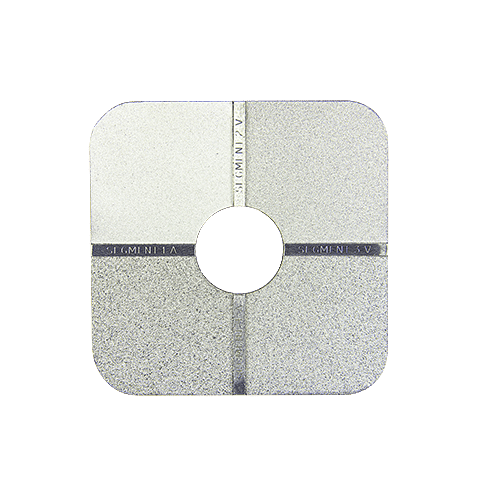

When steel has been blast-cleaned, the surface consists of random irregularities with peaks and valleys that are not easily characterised. Because of this random nature, it is recommended that the profile should be identified as either angular (where grit abrasives have been used) or dimpled (where shot abrasives have been used) and that they should be graded as fine, medium or coarse using the four segments on the Comparator.

Fine-grade profiles equal to segment 1 and up to but excluding segment 2. Medium-grade profiles equal to segment 2 and up to but excluding segment 3. Coarse-grade profiles equal to segment 3 and up to but excluding segment 4.

Information

ISO 8503-1: Preparation of steel substrates before application of paints and related products. Surface roughness characteristics of blast-cleaned steel substrates. Part 1: Specifications and definitions for ISO surface profile comparators for the assessment of abrasive blast-cleaned surfaces.

ISO 8503-2: Preparation of steel substrates before application of paints and related products. Surface roughness characteristics of blast-cleaned steel substrates. Part 2: Method for the grading of surface profile of abrasive blast cleaned steel. Comparator procedure.

A precision nickel Comparator plate for grit and shot-blast surface roughness comparison measurement.

When steel has been blast-cleaned, the surface consists of random irregularities with peaks and valleys that are not easily characterised. Because of this random nature, experts have recommended that the profile should be identified as either angular (where grit abrasives have been used) or dimpled (where shot abrasives have been used) and that they should be graded as fine, medium or coarse with each grade being defined by limits specified in ISO 8503.

The Roughness Comparator is supplied in a protective Wallet.

A X5 Illuminated Magnifier for viewing the Comparator is available has an optional extra.

The 5X Illuminated Magnifier is used for viewing the Roughness Comparator.

Roughness Comparator Specifications

| Model |

Comparator Type |

Profile Segment1 |

Profile Segment2 |

Profile Segment3 |

Profile Segment4 |

Conformance Cert Part No |

| R2006 |

Grit |

25µm |

60µm |

100µm |

150µm |

NRC01 |

| 1mils |

2.4mils |

4mils |

6mils |

|

| R2007 |

Shot |

25µm |

40µm |

70µm |

100µm |

NRC01 |

| 1mils |

1.6mils |

2.8mils |

4mils |

|

| R2011 |

Illuminated Magnifier X5. Includes Carrying Case |

Evaluation

Remove all loose dirt and debris from the test surface.

Select the appropriate surface profile reference Comparator. The Grit Comparator is for comparing profiles after blast-cleaning with grit abrasives, and the Shot Comparator is for comparing profiles after blast-cleaning with shot abrasives.

- Place the selected Comparator against an area of the test surface. Compare in turn the test surface with the four segments of the Comparator, using the Illuminated Magnifier if necessary. If the Illuminated Magnifier is used, place it so that the test surface is viewed simultaneously with a segment of the Comparator.

- Assess the profiles on the Comparator that are nearest to the profile of the test surface and determine its grade from the following:

- Fine-grade profiles equal to segment 1 and up to but excluding segment 2

- Medium-grade profiles equal to segment 2 and up to but excluding segment 3.

- Coarse-grade profiles equal to segment 3 and up to but excluding segment 4.

- If any profile is assessed as below the lower limit for the fine grading, assess this grading as finer than fine.

- If any profile is assessed as greater than the upper limit for the coarse grading, assess this grading as coarser than coarse.

- If visual assessment proves difficult, tactile assessment may provide a useful guide. It is possible to assess the closest grading by passing the back of a fingernail or a wooden stylus held between thumb and forefinger over the test surface and segments on the Comparator alternately.

Roughness Comparator Operation

Care

- Never place the Comparator face down on a rough surface. Keep the Comparator in the protective Wallet provided when not in use.

- If the Comparator becomes tarnished, wash with a Dilute detergent solution and soft brush and dry with soft tissue.

Practical Advice

- The Roughness Comparator method is applicable to steel surfaces that have been blast-cleaned to grades Sa 2½ and Sa 3 when the surface under test shows an overall blast-cleaned appearance.

- It is applicable to surfaces that have been cleaned with either metallic or non-metallic abrasives

- When a mixture of shot and grit abrasives are used to blast-clean a substrate, the Grit Surface Roughness Comparator should be used.

About Us

- Paint Test Equipment is a global leader in the manufacture of specialist test equipment specifically for the industrial painting and coating industries for the protection of steel assets from corrosion, mainly in the oil, renewables and steel construction sectors. We have over 30 years experience and extensive knowledge in delivering practical solutions in supporting our customers with world class products for corrosion prevention.

- Prevention of corrosion on steel is essential to extend the asset lifetime, optimise performance and minimise downtime for expensive maintenance work. Using Paint Test Equipment products ensures that industrial coatings are applied to the highest achievable quality standards of ISO compliance.

- We supply small, medium and multinational companies with the full range of technologies and innovations in our unrivalled portfolio of products for our customers to grow their business and enhance profits through cost effective corrosion management equipment.

- Paint Test Equipment is committed to providing proactive and innovative solutions to meet customer requirements for the highest quality, user friendly inspection equipment. Paint Test Equipment is the partner of choice.

Surface Roughness Tester เครื่องทดสอบความเรียบผิว iSurfa-520

Surface Roughness Tester เครื่องทดสอบความเรียบผิว iSurfa-520  Surface Roughness Tester เครื่องทดสอบความเรียบผิว iSurfa-100

Surface Roughness Tester เครื่องทดสอบความเรียบผิว iSurfa-100  Digital Surface Volume Resistivity Meter เครื่องทดสอบความเรียบ Model MR43 (TRONOVO)

Digital Surface Volume Resistivity Meter เครื่องทดสอบความเรียบ Model MR43 (TRONOVO)  Digital Surface Volume Resistivity Meter เครื่องทดสอบความเรียบ Model MR63 (TRONOVO)

Digital Surface Volume Resistivity Meter เครื่องทดสอบความเรียบ Model MR63 (TRONOVO)  LeebS480 Surface Roughness Tester

LeebS480 Surface Roughness Tester  Surface Roughness Tester เครื่องทดสอบความเรียบ TMR 120

Surface Roughness Tester เครื่องทดสอบความเรียบ TMR 120  Stand Roughness Tester แท่นยึดจับชิ้นงานสำหรับเครื่องทดสอบความเรียบผิว

Stand Roughness Tester แท่นยึดจับชิ้นงานสำหรับเครื่องทดสอบความเรียบผิว  Surface Roughness Tester เครื่องทดสอบความเรียบ Model TMR-360 (TMTECK)

Surface Roughness Tester เครื่องทดสอบความเรียบ Model TMR-360 (TMTECK)  Surface Roughness Tester เครื่องทดสอบความเรียบ Model TIME3223

Surface Roughness Tester เครื่องทดสอบความเรียบ Model TIME3223  Surface Roughness Tester เครื่องทดสอบความเรียบ Model TIME3220

Surface Roughness Tester เครื่องทดสอบความเรียบ Model TIME3220  Surface Roughness Tester เครื่องทดสอบความเรียบ Model TIME3210

Surface Roughness Tester เครื่องทดสอบความเรียบ Model TIME3210  Surface Roughness Tester เครื่องทดสอบความเรียบ Model TIME3110

Surface Roughness Tester เครื่องทดสอบความเรียบ Model TIME3110  Surface Roughness Tester เครื่องทดสอบความเรียบ Model TIME3221

Surface Roughness Tester เครื่องทดสอบความเรียบ Model TIME3221  Surface Roughness Tester เครื่องทดสอบความเรียบ Model TIME3233

Surface Roughness Tester เครื่องทดสอบความเรียบ Model TIME3233  Surface Roughness Tester เครื่องทดสอบความเรียบ Model TIME3231

Surface Roughness Tester เครื่องทดสอบความเรียบ Model TIME3231  Surface Roughness Tester เครื่องทดสอบความเรียบ Model TIME3234

Surface Roughness Tester เครื่องทดสอบความเรียบ Model TIME3234  Surface Roughness Tester เครื่องทดสอบความเรียบ Model DR-300

Surface Roughness Tester เครื่องทดสอบความเรียบ Model DR-300  Surface Roughness Tester เครื่องทดสอบความเรียบ Model SRT-350

Surface Roughness Tester เครื่องทดสอบความเรียบ Model SRT-350  Surface Roughness Tester Laser Check เครื่องทดสอบความเรียบผิว

Surface Roughness Tester Laser Check เครื่องทดสอบความเรียบผิว  Surface Roughness Tester เครื่องทดสอบความเรียบผิว Model TRL-400

Surface Roughness Tester เครื่องทดสอบความเรียบผิว Model TRL-400  Surface Roughness Tester เครื่องทดสอบความเรียบ Model PRSR-110

Surface Roughness Tester เครื่องทดสอบความเรียบ Model PRSR-110  Surface Roughness Tester เครื่องทดสอบความเรียบ Model TMR-200

Surface Roughness Tester เครื่องทดสอบความเรียบ Model TMR-200  Surface Roughness Tester เครื่องทดสอบความเรียบ Model AR-132C

Surface Roughness Tester เครื่องทดสอบความเรียบ Model AR-132C  Surface Roughness Tester เครื่องทดสอบความเรียบ Model AR-132B

Surface Roughness Tester เครื่องทดสอบความเรียบ Model AR-132B  Surface Roughness Tester เครื่องทดสอบความเรียบ Model SRT-200

Surface Roughness Tester เครื่องทดสอบความเรียบ Model SRT-200  Surface Roughness Tester เครื่องทดสอบความเรียบ Model TR-200

Surface Roughness Tester เครื่องทดสอบความเรียบ Model TR-200  Surface Roughness Tester เครื่องทดสอบความเรียบ Model IS-14131

Surface Roughness Tester เครื่องทดสอบความเรียบ Model IS-14131  Surface Roughness Tester เครื่องทดสอบความเรียบ Model SRT-6210

Surface Roughness Tester เครื่องทดสอบความเรียบ Model SRT-6210  Surface Roughness Tester เครื่องทดสอบความเรียบ Model PTS 103 PTS 104

Surface Roughness Tester เครื่องทดสอบความเรียบ Model PTS 103 PTS 104

.png)