|

| เครื่องวัดชิ้นงานละเอียดเสมือนจริง Vido Measuring Machine QT-Series เครื่องวัดชิ้นงานละเอียดเสมือนจริง Vido Measuring Machine QT-Series QT Instant Video Measuring Machine Flat Dimensional Fast Measurement Solution

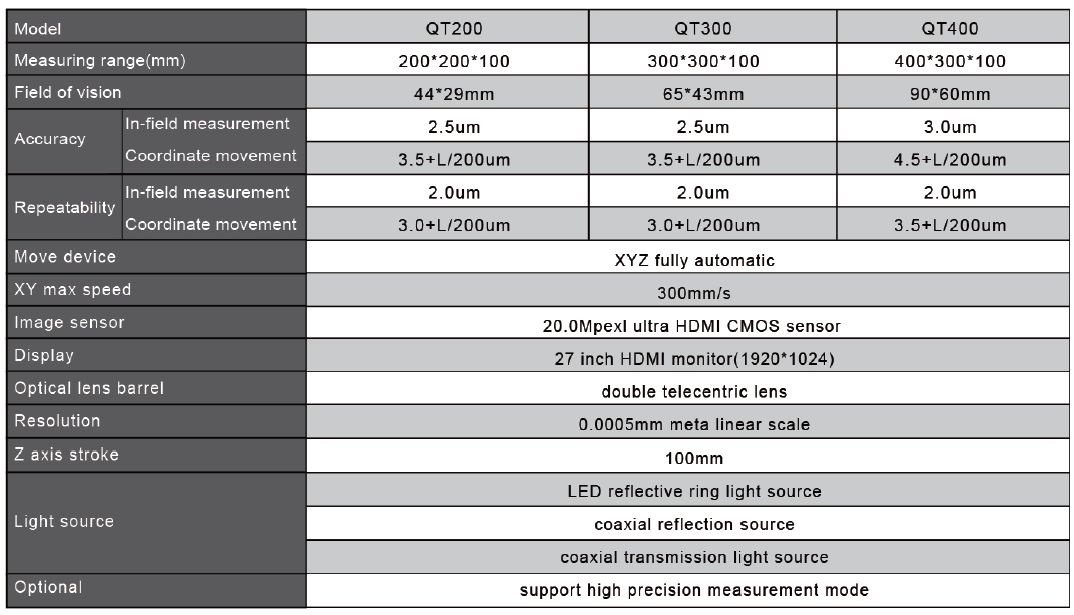

QT200 measuring range: 200x200 mm QT300 measuring range: 300x300 mm QT400 measuring range: 400x300 mm QT ใช้ระบบออปติคัลแบบไม่สัมผัสซึ่งประกอบด้วย CCD และแสงเส้นขอบแบบขนาน และดำเนินการสแกนการวัดในแนวตั้ง • The machine architecture

|

เครื่องวัดชิ้นงานงานละเอียดเสมือนจริง Video Measuring Machine MINI-Series (SUNPOC) เครื่องวัดชิ้นงานงานละเอียดเสมือนจริง Video Measuring Machine MINI-Series (SUNPOC)  เครื่องวัดชิ้นงานเสมือนจริง Full Automatic Dual FOV QTD-4030P เครื่องวัดชิ้นงานเสมือนจริง Full Automatic Dual FOV QTD-4030P  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine Manual VMH-CNC (Mikrosize) เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine Manual VMH-CNC (Mikrosize)  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine Manual VMC-CNC (Mikrosize) เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine Manual VMC-CNC (Mikrosize)  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine Manual VMG-CNC (Mikrosize) เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine Manual VMG-CNC (Mikrosize)  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine Manual VMU-CNC (Mikrosize) เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine Manual VMU-CNC (Mikrosize)  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine Manual VMA-F Semi Automatic (Mikrosize) เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine Manual VMA-F Semi Automatic (Mikrosize)  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine Manual VMA(Mikrosize) เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine Manual VMA(Mikrosize)  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine MANUAL GZ4030 + MCP PROBE เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine MANUAL GZ4030 + MCP PROBE  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine MANUAL GZ4030 เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine MANUAL GZ4030  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine MANUAL GZ3020 เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine MANUAL GZ3020  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine CNC VMS432H + TOUCH PORBE เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine CNC VMS432H + TOUCH PORBE  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine CNC VMS322H เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine CNC VMS322H  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine CNC VMS432H เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine CNC VMS432H  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Vido Measuring Machine MC-ME-Series เครื่องวัดชิ้นงานละเอียดเสมือนจริง Vido Measuring Machine MC-ME-Series  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Vido Measuring Machine FQT-Series เครื่องวัดชิ้นงานละเอียดเสมือนจริง Vido Measuring Machine FQT-Series  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Vido Measuring Machine QM-Series เครื่องวัดชิ้นงานละเอียดเสมือนจริง Vido Measuring Machine QM-Series  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Vido Measuring Machine AGM-Series เครื่องวัดชิ้นงานละเอียดเสมือนจริง Vido Measuring Machine AGM-Series  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Vido Measuring Machine SLA-Series เครื่องวัดชิ้นงานละเอียดเสมือนจริง Vido Measuring Machine SLA-Series  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Vido Measuring Machine LA-Series เครื่องวัดชิ้นงานละเอียดเสมือนจริง Vido Measuring Machine LA-Series  เครื่องวัดชิ้นงานละเอียด Vision Measurement ITK-VX3030D Series เครื่องวัดชิ้นงานละเอียด Vision Measurement ITK-VX3030D Series  เครื่องวัดชิ้นงานละเอียด Vision Measurement ITK-VX3100D Series เครื่องวัดชิ้นงานละเอียด Vision Measurement ITK-VX3100D Series  เครื่องวัดชิ้นงานละเอียด Vision Measurement ITK-VX4000 Series เครื่องวัดชิ้นงานละเอียด Vision Measurement ITK-VX4000 Series  เครื่องวัดชิ้นงานละเอียด Vision Measurement ITK-IVS867 เครื่องวัดชิ้นงานละเอียด Vision Measurement ITK-IVS867  เครื่องวัดชิ้นงานละเอียด Vision Measurement ITK-IVS327 เครื่องวัดชิ้นงานละเอียด Vision Measurement ITK-IVS327  เครื่องวัดชิ้นงานละเอียด Vision Measurement ITK-IVS227 เครื่องวัดชิ้นงานละเอียด Vision Measurement ITK-IVS227  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine AG-Series เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine AG-Series  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine Instant Video เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine Instant Video  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine AM-CNC เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine AM-CNC  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine S-Series เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine S-Series  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine AC-Series เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine AC-Series  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine Vision System Machine ITK-QT เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine Vision System Machine ITK-QT  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine W-Series เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine W-Series  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine A-SERIES เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine A-SERIES  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine 3D Surfiew เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine 3D Surfiew  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine M-SERIES เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine M-SERIES  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine Instant Vision Measuring System เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine Instant Vision Measuring System  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine E-SERIES เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine E-SERIES  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine SP-VMH เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine SP-VMH  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine VMC-SERIES เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine VMC-SERIES  กล้องวัดขนาดชิ้นงาน แบบเคลื่อนที่ Video Measuring Machine PORTABLE2010 กล้องวัดขนาดชิ้นงาน แบบเคลื่อนที่ Video Measuring Machine PORTABLE2010  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine VMT-SERIES เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine VMT-SERIES  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine VMC-L เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine VMC-L  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine VMZ-SERIES เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine VMZ-SERIES |