|

| เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine Instant Vision Measuring System เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine Instant Vision Measuring System Instant Vision Measuring System Model: SQM‐30, SQM‐60, SQM‐80, SQM‐160

กล้องวัดขนาดชิ้นงาน ละเอียดสูง แบบอัตโนมัติ สามารถวัดชิ้นงาน ได้แบบ อัตโนมัติ และสามารถแยกงานดี งานเสีย ได้ที ละหลายตัว สำหรับชิ้นงานเล็กๆ โดยเฉพาะ

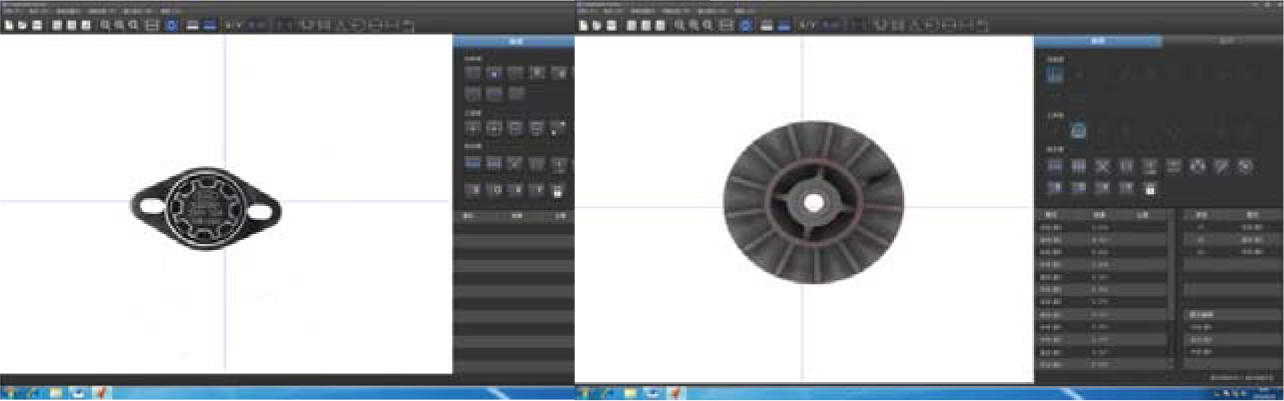

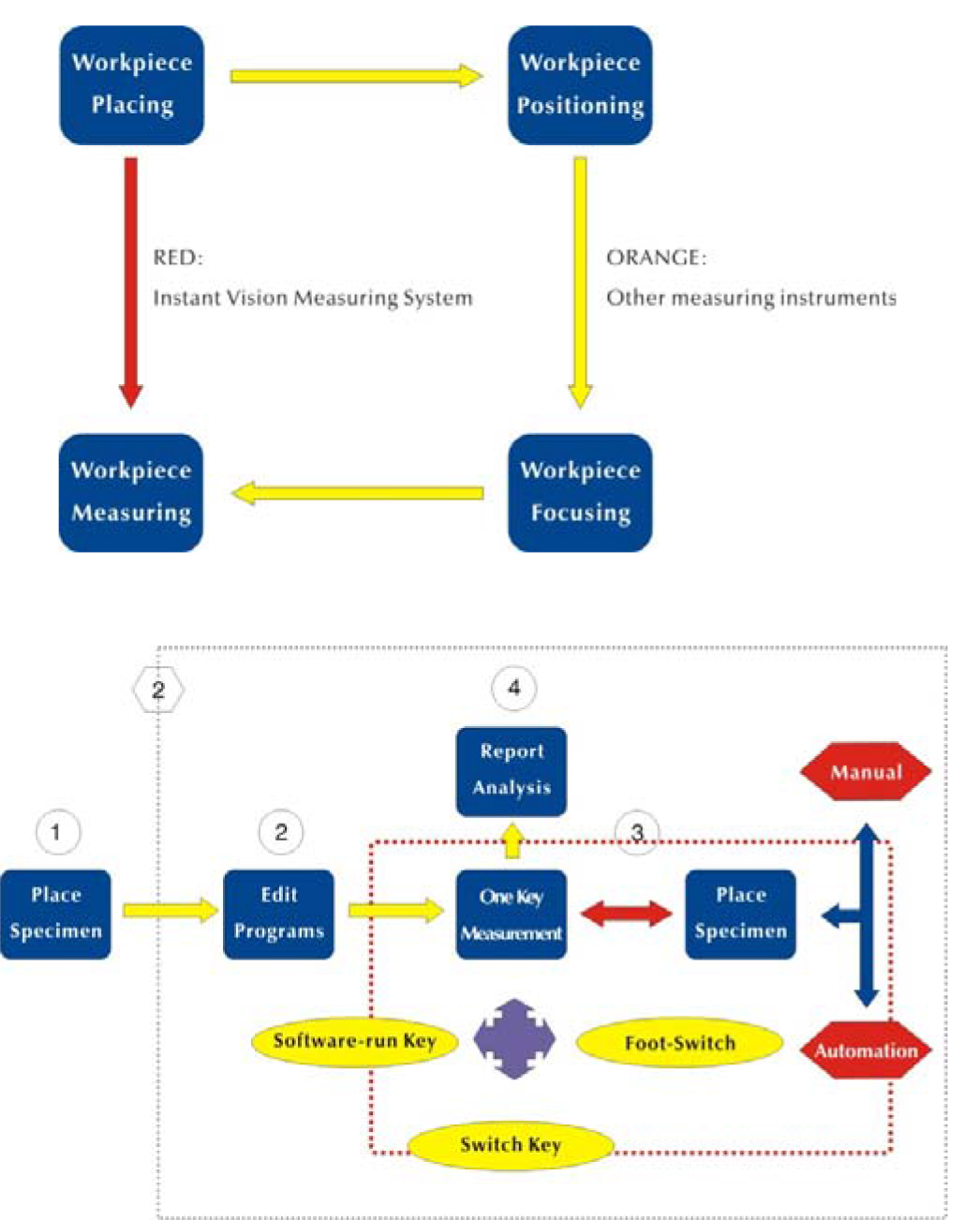

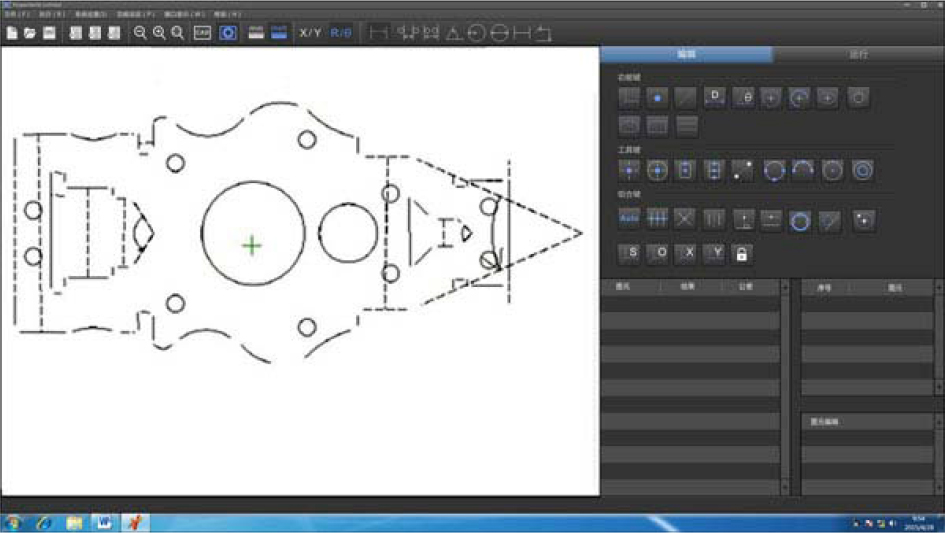

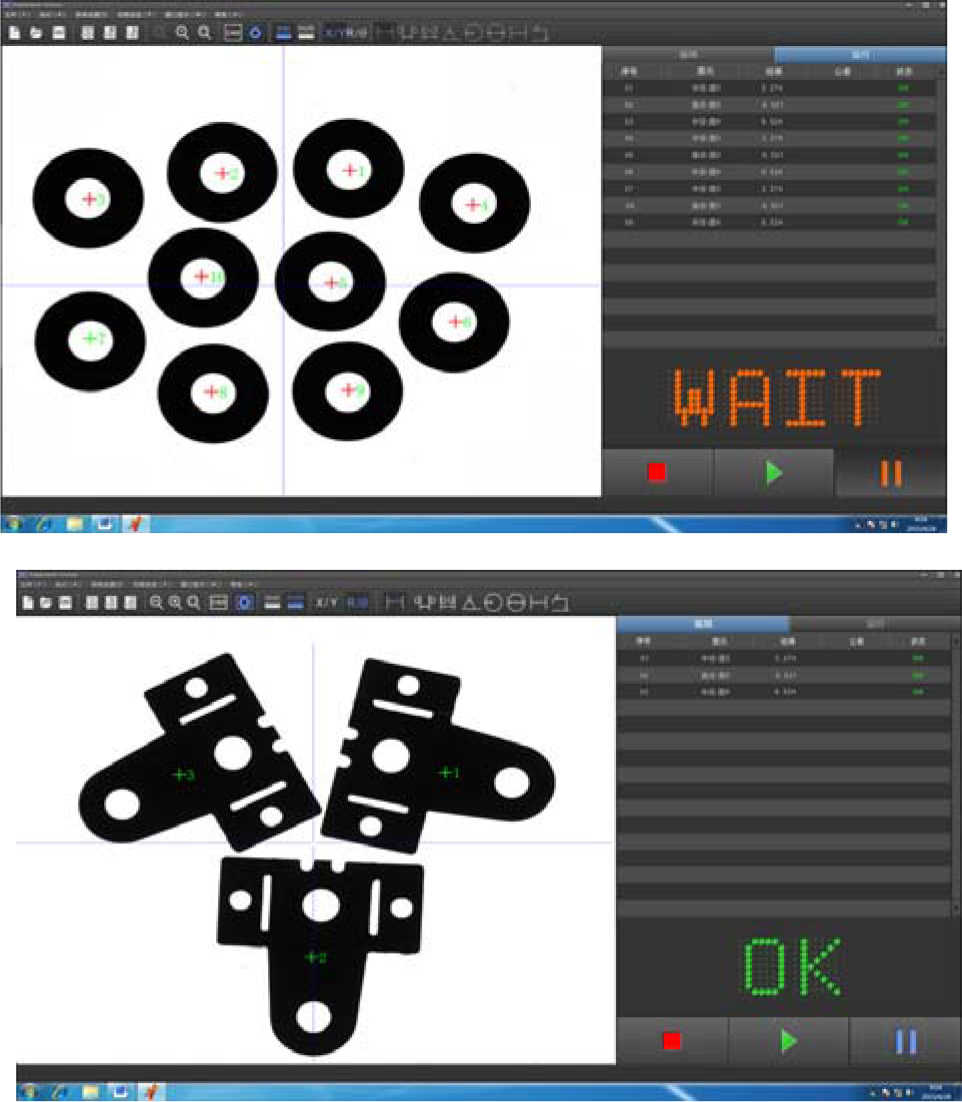

Instant Vision Measuring System Features: 1. ficient Batch Measurement: All dimensions can be detected and measured simultaneously and automatically, even the samples are placed randomly. Workpiece Placin, No location and Fixture requirements, anywhere within the effective range of the lens; Workpiece positioning—— Automatic location and orientation correction, automatically detected and measured based on the recorded shape of the sample; Workpiece Focusing——Double telecentric lens, long working distance, allow height difference; Workpiece Measuring——Entire image reduce the time of import programe, moving worktable and lens.

คุณสมบัติ ทุกมิติสามารถตรวจพบและวัดพร้อมกันและโดยอัตโนมัติแม้ว่ากลุ่มตัวอย่างจะถูกวางไว้แบบสุ่ม ชิ้นงาน Placin สถานที่ไม่มีตารางการแข่งขันและความต้องการที่ใดก็ได้ภายในช่วงที่มีประสิทธิภาพของเลนส์

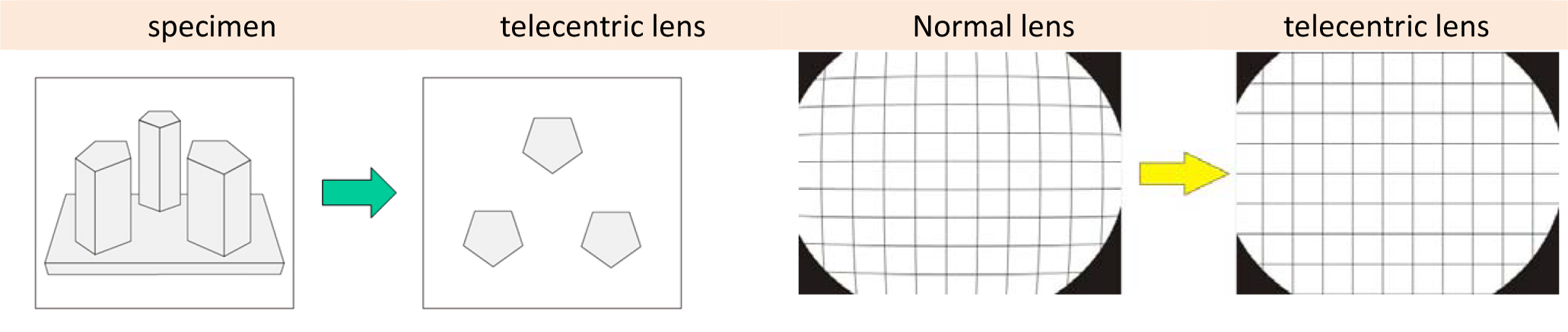

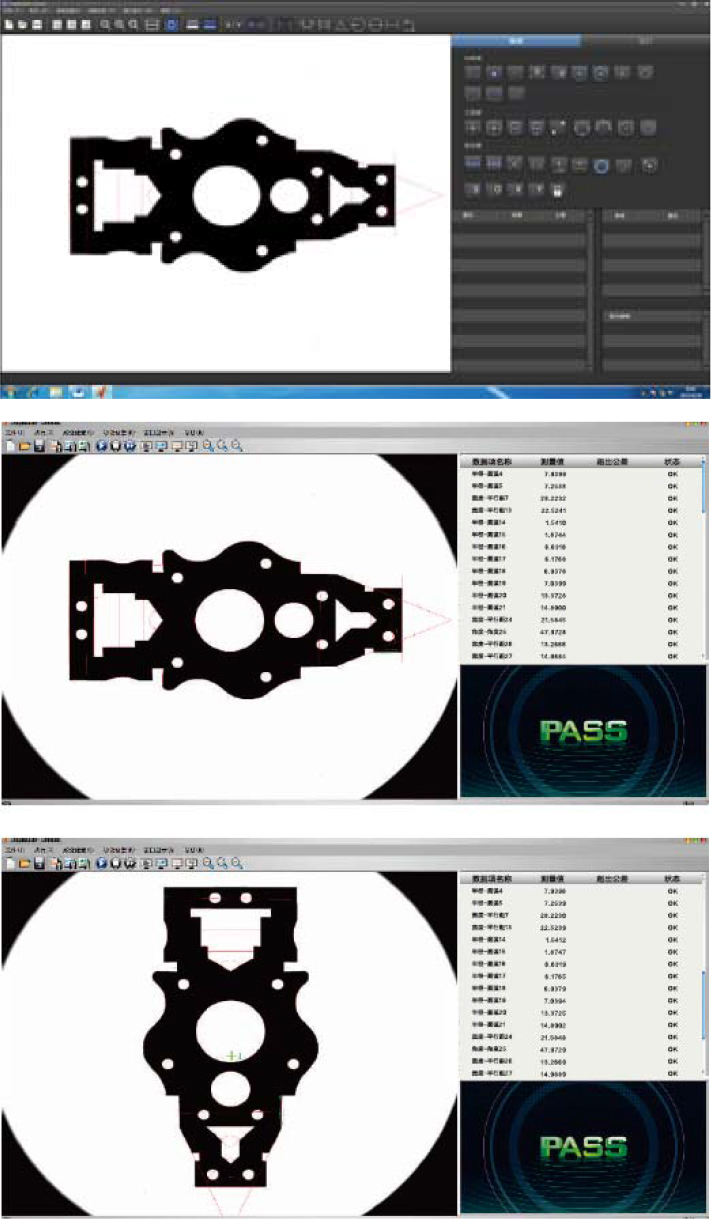

2. Effectively Eliminate Operator Error: 3. Friendly Operation, Low Costs: 4. Perfect Accuracy; Double telecentric lens, low distortion , high accuracy. Double telecentric lens, allow the sample height difference, section with slope or curvature and other difficult measuring elements. ● Low distortion without having to worry about sample placement and blurred focus, and restore the true dimensions of products, high accuracy. 5. Entire Image: This is a new measurement system which measures by capturing the entire image of a sample within the field of view. ● Traditional measuring instruments have narrow field of vision, can only test one position at a time,and it requires to move working stage and position specimen before measuring; ● Repeatable steps and more time‐consuming and complex to operate; ● Need to consider the accuracy of supporting hardware, such as, linear scales, working stage mounting accuracy, etc. Can image overall within the maximum range of the measuring field, measurement of multiple sizes can be finished at once, greatly improve efficiency, save time and cost of production.Meanwhile, it meets customers idea "without mosaic, overall image". 6. Batch Measurement: Software is for automatic saving shape of specimen,automatic positioning,direction detecting, the coordinate origin for repeated measurements. Takes only seconds to measure dozens of position, 99 measurements can be conducted at a time within the measuring range; Simultaneous measurement can be conducted multiple identical specimens within the perspective. 7. Simple Application: Convenient applications of measurement data, automatically saves test data and print test reports and SPC data charts for quality control. 8, Support Reverse Engineering: Imported DXF files by software can be measured, graph and data can also be exported from the software for DXF files for other applications.

|

เครื่องวัดชิ้นงานเสมือนจริง Full Automatic Dual FOV QTD-4030P เครื่องวัดชิ้นงานเสมือนจริง Full Automatic Dual FOV QTD-4030P  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine Manual VMH-CNC (Mikrosize) เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine Manual VMH-CNC (Mikrosize)  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine Manual VMC-CNC (Mikrosize) เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine Manual VMC-CNC (Mikrosize)  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine Manual VMG-CNC (Mikrosize) เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine Manual VMG-CNC (Mikrosize)  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine Manual VMU-CNC (Mikrosize) เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine Manual VMU-CNC (Mikrosize)  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine Manual VMA-F Semi Automatic (Mikrosize) เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine Manual VMA-F Semi Automatic (Mikrosize)  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine Manual VMA(Mikrosize) เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine Manual VMA(Mikrosize)  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine MANUAL GZ4030 + MCP PROBE เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine MANUAL GZ4030 + MCP PROBE  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine MANUAL GZ4030 เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine MANUAL GZ4030  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine MANUAL GZ3020 เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine MANUAL GZ3020  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine CNC VMS432H + TOUCH PORBE เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine CNC VMS432H + TOUCH PORBE  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine CNC VMS322H เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine CNC VMS322H  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine CNC VMS432H เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine CNC VMS432H  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Vido Measuring Machine MC-ME-Series เครื่องวัดชิ้นงานละเอียดเสมือนจริง Vido Measuring Machine MC-ME-Series  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Vido Measuring Machine FQT-Series เครื่องวัดชิ้นงานละเอียดเสมือนจริง Vido Measuring Machine FQT-Series  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Vido Measuring Machine QM-Series เครื่องวัดชิ้นงานละเอียดเสมือนจริง Vido Measuring Machine QM-Series  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Vido Measuring Machine QT-Series เครื่องวัดชิ้นงานละเอียดเสมือนจริง Vido Measuring Machine QT-Series  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Vido Measuring Machine AGM-Series เครื่องวัดชิ้นงานละเอียดเสมือนจริง Vido Measuring Machine AGM-Series  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Vido Measuring Machine SLA-Series เครื่องวัดชิ้นงานละเอียดเสมือนจริง Vido Measuring Machine SLA-Series  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Vido Measuring Machine LA-Series เครื่องวัดชิ้นงานละเอียดเสมือนจริง Vido Measuring Machine LA-Series  เครื่องวัดชิ้นงานละเอียด Vision Measurement ITK-VX3030D Series เครื่องวัดชิ้นงานละเอียด Vision Measurement ITK-VX3030D Series  เครื่องวัดชิ้นงานละเอียด Vision Measurement ITK-VX3100D Series เครื่องวัดชิ้นงานละเอียด Vision Measurement ITK-VX3100D Series  เครื่องวัดชิ้นงานละเอียด Vision Measurement ITK-VX4000 Series เครื่องวัดชิ้นงานละเอียด Vision Measurement ITK-VX4000 Series  เครื่องวัดชิ้นงานละเอียด Vision Measurement ITK-IVS867 เครื่องวัดชิ้นงานละเอียด Vision Measurement ITK-IVS867  เครื่องวัดชิ้นงานละเอียด Vision Measurement ITK-IVS327 เครื่องวัดชิ้นงานละเอียด Vision Measurement ITK-IVS327  เครื่องวัดชิ้นงานละเอียด Vision Measurement ITK-IVS227 เครื่องวัดชิ้นงานละเอียด Vision Measurement ITK-IVS227  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine AG-Series เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine AG-Series  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine Instant Video เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine Instant Video  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine AM-CNC เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine AM-CNC  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine S-Series เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine S-Series  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine AC-Series เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine AC-Series  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine Vision System Machine ITK-QT เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine Vision System Machine ITK-QT  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine W-Series เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine W-Series  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine A-SERIES เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine A-SERIES  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine 3D Surfiew เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine 3D Surfiew  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine M-SERIES เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine M-SERIES  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine E-SERIES เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine E-SERIES  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine SP-VMH เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine SP-VMH  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine VMC-SERIES เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine VMC-SERIES  กล้องวัดขนาดชิ้นงาน แบบเคลื่อนที่ Video Measuring Machine PORTABLE2010 กล้องวัดขนาดชิ้นงาน แบบเคลื่อนที่ Video Measuring Machine PORTABLE2010  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine VMT-SERIES เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine VMT-SERIES  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine VMC-L เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine VMC-L  เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine VMZ-SERIES เครื่องวัดชิ้นงานละเอียดเสมือนจริง Video Measuring Machine VMZ-SERIES |