WireTerminal WT3-201 MANUAL

เครื่องทดสอบการดึงสายไฟ

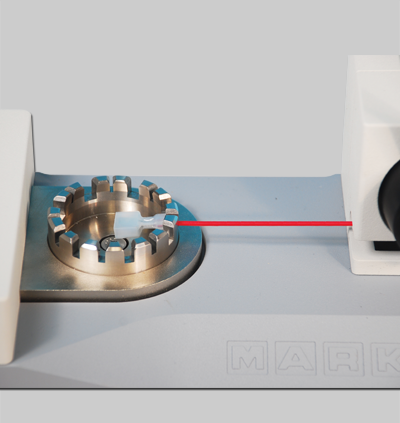

The WT3-201 Wire Terminal Tester accurately measures the pull-off force off crimped-on wire terminals. The pull tester is an easy to use all-in-one, single-range solution for a wide range terminal testing applications, eliminating the need to purchase any additional grips, fixtures or accessories. An ergonomic lever allows for easy application of up to 200 lbF (1,000 N) of pull force. Adjustable wire terminal grip contains multiple slots for wire diameters up to AWG 3 (0.25 in [6.3 mm]).

A large, backlit graphic LCD displays easy-to-read values, including real-time force, peak force, programmable pass/fail limits, units of measurement, and more. Data can be transferred to a PC or other data collector via USB, RS-232 or analog outputs.

On-board data storage for up to 1,000 readings is included, as are statistical calculations and output to a PC. Unique automatic output / data storage / zeroing upon sample break helps automate testing processes.

An optional ring terminal fixture may be used to secure ring terminations, and an optional carrying case makes transportation simple and safe.

The WT3-201 is an alternative to the Daniels PT-150H Wire Crimp Pull Tester.

.png)

Features

- Includes NIST Traceable Calibration Certificate (without data)

- Optional Long-Form Cert with data available, order "CERT"

- Automatic output / data storage / zeroing upon sample break helps automate testing processes

- Measures real-time and peak force values

- USB, RS-232, Mitutoyo (Digimatic), and analog outputs

- 1,000-point data memory with statistics and outputs

- Programmable set point indicators and outputs for pass/ fail determination

- Configurable audio alarms and key tones

- Ergonomic lever operation produces 200 lbF [1000 N]

- Password protection prevents unauthorized changes

- High-speed 7,000 Hz sampling rate accurately captures peak force values

- Mounting holes for bench mounting

- CE Certified

Specifications

| Capacity x Resolution |

200 x 0.1 lbF, 100 x 0.05 kgF, 1000 x 0.5 N |

| Accuracy |

±0.2% of full scale |

| Wire diameter range |

AWG30 - AWG 3 [0.03 - 0.25 in (0.8 - 6.3 mm)]* |

| Minimum sample length |

6.5 in [165 mm], excluding termination |

| Maximum sample elongation |

1.15 in [29.2 mm] |

| Power |

AC or rechargeable battery. Multi-step low battery indicator is displayed, gauge shuts off automatically when power is too low. |

| Battery Life |

Backlight on: up to 7 hours of continuous use

Backlight off: up to 24 hours of continuous use |

| Sampling rate |

7,000 Hz |

| Outputs |

USB / RS-232: Configurable up to 115,200 baud.

Mitutoyo (Digimatic): Serial BCD suitable for all Mitutoyo SPC-compatible Devices.

Analog: ±1V DC, ±0.25% of full scale at capacity. |

| Configurable Settings |

Digital filters, outputs, automatic shutoff, default settings, passwords, key tones, audio alarms, backlight, calibration |

| Safe overload |

150% of full scale (display shows "OVER" at 110% and above) |

| Weight |

16.1 lb [7.3 kg] |

| Warranty |

3 years (see individual statement for further details) |

| Included items |

Universal voltage AC adapter, battery, quick-start guide, USB cable, resource CD (USB driver, MESUR™Lite software, MESUR™gauge DEMO software, and user's guide), NIST-traceable certificate of calibration |

*Including insulation. To ensure the wire sample will fit into the WT3-201, measure the overall outside diameter of the insulated wire and check against the specified diameter range. Account for sample compressibility in making this determination.

WireTerminal WTT-FGS

WireTerminal WTT-FGS  WireTerminal WTT

WireTerminal WTT  WireTerminal WTT-ESMHD

WireTerminal WTT-ESMHD  WireTerminal WTT-ESM

WireTerminal WTT-ESM  WireTerminal WTT-110

WireTerminal WTT-110  WireTerminal WTT-BX

WireTerminal WTT-BX  WireTerminal WT3-200

WireTerminal WT3-200  WireTerminal WTTM-GEN1

WireTerminal WTTM-GEN1  WireTerminal WTTM

WireTerminal WTTM  WireTerminal ACT-220

WireTerminal ACT-220  WireTerminal WT3-201M

WireTerminal WT3-201M

.png)